- Hydraulics - Pneumatics

- Filter and Separator

- Centrifugal separator

- Eaton Filtration Solutions

- Products

- Catalogs

- News & Trends

- Exhibitions

Centrifugal separator Type Lliquidsgasprocess

Add to favorites

Compare this product

Characteristics

- Technology

- centrifugal

- Separated substance

- liquids, gas

- Application domain

- process

- Other characteristics

- compact, low-profile

- Filtration size

10 µm

Description

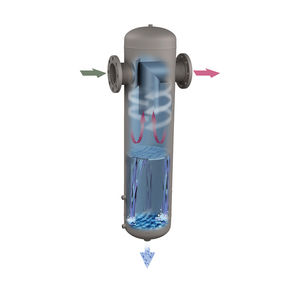

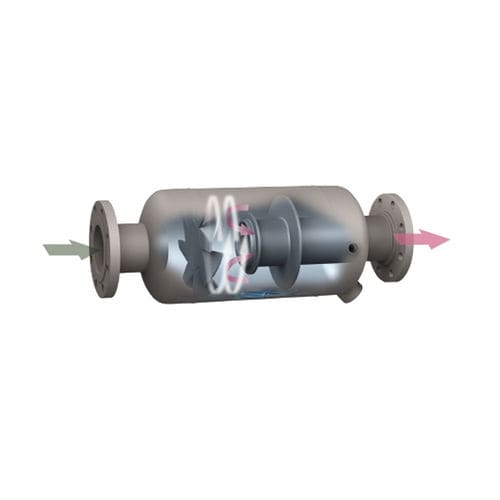

Eaton's in-line Gas/Liquid Separator Type L automatically removes 99% of all liquid and solid entrainment particles 10 microns in size or larger. And it does so with no moving parts to break or wear out.

Series L Gas/Liquid Separators perform to specification year in and year out with no maintenance.

The Eaton Type L Gas Liquid Separator series can be installed horizontally or vertically for down flow applications.

Core features

Low-profile, compact design

No moving parts to wear out, no required maintenance

When properly sized, installed, and drained, will remove up to 99% of all liquid and solid entrainment where particle size exceeds 10 microns

Ten different models to match the needs of any application’s flow direction or piping system orientation

Exclusive Vortex Containment Plate (VCP) System

Applications

Steam drums

Steam turbines

Intercooler equipment

Aftercooler equipment

Gas well heads

Deep well heads

Oil extraction

Chemical processing

Scrubbing systems

Evaporator

Glycol dehydration

Sulfur condenser

Mist elimination

Heat exchangers

Reactors

Landfill/waste gas

VIDEO

Other Eaton Filtration Solutions products

Gas Liquid Separators

Related Searches

- Eaton liquid filter

- Filter with cartridge

- Filter cartridge

- Solid classifier

- Industrial filter cartridge

- Pressure separator filter

- Filter for industrial applications

- Centrifugal classifier

- Stainless steel separator filter

- Fine filter cartridge

- Liquids separator

- Eaton filter housing

- Eaton filtration unit

- Eddy current separator

- General purpose filter cartridge

- Water filter cartridge

- Cartridge filter housing

- Eaton liquid filter housing

- Plastic filter cartridge

- Y-strainer filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.