- Hydraulics - Pneumatics

- Filter and Separator

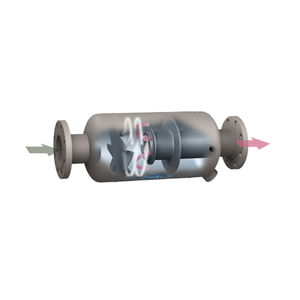

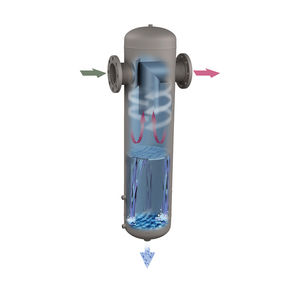

- Centrifugal separator and drain

- Eaton Filtration Solutions

- Products

- Catalogs

- News & Trends

- Exhibitions

Centrifugal separator and drain AC/ACN series condensateliquid waste collectioncast iron

Add to favorites

Compare this product

Characteristics

- Technology

- centrifugal

- Separated substance

- condensate

- Application domain

- liquid waste collection

- Other characteristics

- cast iron

Description

Eaton Float Drain Traps efficiently handle the liquids in the storage tanks and drip points of separators without pressure loss in the line. These traps are capable of removing up to 2800 pounds of condensate per hour and work with pressure differentials from 5 up to 250 psi.

Float Drain Traps are available in a variety of models and materials of construction, featuring the Model 90-AC, Model 95-AC and Model 230-AC.

Core features

No priming required

Stainless steel internal parts are corrosion-resistant

Internal parts attached to cover for easy removal and inspection

No loss of line pressure

Choice of inlet/outlet configurations

Key Separator Applications:

Steam drums

Steam turbines

Intercooler equipment

Aftercooler equipment

Gas well heads

Deep well heads

Oil extraction

Chemical processing

Scrubbing systems

Evaporator

Glycol dehydration

Sulfur condenser

Mist elimination

Heat exchangers

Reactors

Landfill/waste gas

Other Eaton Filtration Solutions products

Gas Liquid Separators

Related Searches

- Eaton liquid filter

- Filter with cartridge

- Filter cartridge

- Solid classifier

- Industrial filter cartridge

- Filter for industrial applications

- Pressure separator filter

- Centrifugal classifier

- Stainless steel separator filter

- Fine filter cartridge

- Liquids separator

- Eaton filter housing

- Eaton filtration unit

- Eddy current separator

- General purpose filter cartridge

- Water filter cartridge

- Cartridge filter housing

- Eaton liquid filter housing

- Plastic filter cartridge

- Y-strainer filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.