- Metrology - Laboratory

- Metrology and Test Equipment

- Quality testing machine

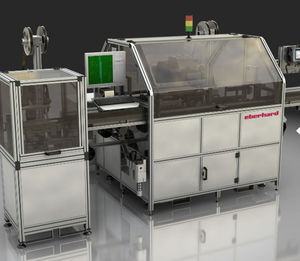

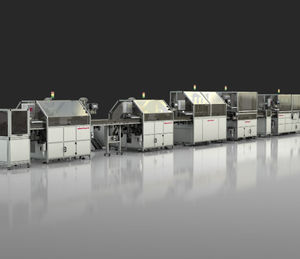

- Eberhard AG Automations- und Montagetechnik

Quality testing machine solid-statelasermechanical

Add to favorites

Compare this product

Characteristics

- Test type

- quality

- Technology

- solid-state, laser, mechanical

- Other characteristics

- precision

Description

CONNECTOR TESTING

Breaking boundaries: our inspection modules detect each deviation of the workpiece’s defined quality standards. Thereby offering you production safety for your end products. Low maintenance and easy to change tools increase the cost efficiency of your production processes.

FUNCTIONS

- PIN POSITION TEST

Inspection of pin position relative to other pins and housing (swash circumference check / true position test).

Methods:

2D/3D Camera

Mask inspection (mechanical / electrical)

3D line laser

- PIN LENGTH TEST

Checking of pin length on the mating and soldering side of the connector.

Methods:

3D Camera

Line laser (with / without adapter)

- ELECTRICAL TESTING

Pin-to-pin testing for electrical functionality.

Test specifications:

Short circuit test (1.500 VDC)

Continuity test (24 VDC)

Presence check for pins and contacts

- CODE / HOUSING COLOR CHECK

Verification of the code’s geometry and color of the connector housing for more production safety.

Methods:

Mechanical mask (tactile method)

Vision sensor / color sensor (non-tactile method)

OPTIONS

- MARKING*

Connectors, headers and plugs can be marked, labelled or numbered according to testing results, with either:

Mechanical marking

Inkjet marking

Laser marking (CO2–laser / solid-state laser)

- SELF-CHECK MODE*

The test mode or the so-called dummy mode enables you a periodic check of the machine’s precision. No interrupting of the production process is necessary. The test can be done automatically or semi-automatically.

- CLEANING*

Our inspection machines can be equipped with cleaning stations – for perfect technical cleanliness of connectors, headers and plugs.

Catalogs

No catalogs are available for this product.

See all of Eberhard AG Automations- und Montagetechnik‘s catalogsOther Eberhard AG Automations- und Montagetechnik products

MACHINES

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.