- Products

- Catalogs

- News & Trends

- Exhibitions

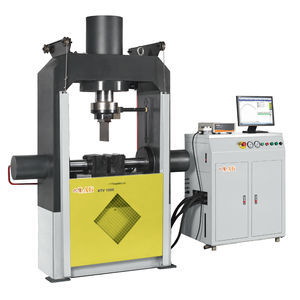

Brugger pendulum impact tester ITM-MP seriesfor Charpy testingfor IZOD testing

Add to favorites

Compare this product

Characteristics

- Type

- Brugger

- Applications

- for Charpy testing, for IZOD testing

Description

>>Charpy and Izod

>>Tensile impact test

>>Wedge impact test of adhesive bond

>>Brugger method test of toothed gear wheels

>>fully complying to ISO 148, ISO 14556, ISO 11343, >EN 10045, ASTM E23, ASTM E1820, ASTM E2298, GOST 9574, JIS Z 2242, JIS B 7722 with impact energy 150J, 300J, 450J, 600J and 750J.

>>Heavy solid steel base machine structure for anvil and heavy-duty cast steel uprights supports.

>>Structure designed to change different pendulums easily.

>>Impact testing machines equipped with electromagnetic hammer release system and clutch for locking and raising to initial position, dumper to prevent strong bump.

>>ITM-MP series equipped with Siemens PLC for tester controls and with high precision rotary encoder NEMICON, to measure the angle with resolution of 0.025° to ensure high accuracy of impact energy

Three versions available:

- ITM-MPD with analogue dial gauge and touch screen display

- ITM-MPC with computer connection and software echoTestPilot .

- ITM-MPI with instrumented impact system consisting in striking knife with force transducer, data sampling card, signal conditioner and test software.

>>For all versions are available, as optional, automatic specimen feeding systems and the related automatic cooling systems up to -180°C, combined with software allow fully automatic impact testing.

>>ITM-MP series supplied with pendulums projected to ensure accurate striking point and moment.

>>High stiffness pendulum rod, no vibration after impact.

>>450J pendulum consists in 300J pendulum with two counter weights. This flexible design facilitates switching impact energy.

Catalogs

ITM-MP series

6 Pages

Related Searches

- Test machine

- Test cabinet

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- Temperature test cabinet

- Benchtop indentation hardness tester

- Digital hardness tester

- Vertical test machine

- Universal test machine

- Tensile test machine

- Flexure testing machine

- Rockwell indentation hardness tester

- Brinell indentation hardness tester

- Environmental test cabinet

- Vickers indentation hardness tester

- Hydraulic test machine

- Automatic indentation hardness tester

- Plastic test machine

- Portable indentation hardness tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.