Targeted lubrication of metal coils and blanks

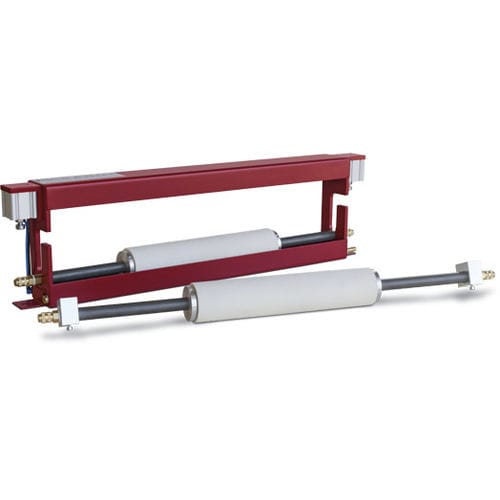

We offer felt roller lubricators in a variety of different model ranges. The rollers are generally driven by the feed machine, but we also offer systems equipped with their own transport units.

Features & benefits

• Different roller diameters available

• Versions with their own transport unit

• Rollers easily and quickly changed

• Rugged, wear-resistant workmanship

• Numerous application options for coil gauges from 0.5 to 10 mm

• Viscosities up to 150 mm2/sec possible

Design versions and details

In this field we offer three product lines with different roller diameters.

32 Series

Our compact felt roller lubricators are designed for coil gauges up to 0.5 mm as well as viscosities up to 100 mm2/sec (recommended guideline values).

Fields of application

Contact components: tab connectors, electric switching contacts, contact springs

Punched and bent parts: medical technology, microelectronics, precision engineering

Fine blanked parts: gear/engine technology, pumps

60 Series

Our medium-sized felt roller lubricators are designed for coil gauges up to 2 mm as well as viscosities up to 120 mm2/sec (recommended guideline values).

Fields of application

Tool making: components for milling/turning/grinding machines

Expanding metals for use in energy technology, chemistry, medicine

Stamped parts for household appliances

110 Series

Our large felt roller lubricators are designed for coil gauges up to 10 mm and viscosities of up to 150 mm2/sec (recommended guideline values).

Fields of application

Structural components for the automotive industry: handles, heat shields, oil pans, etc.

Fittings for household appliances