- Hydraulics - Pneumatics

- Filter and Separator

- Air biofilter

- Ecochimica System

Air biofilter BIO-COMP®particulatemembrane

Add to favorites

Compare this product

Characteristics

- Designed for

- air, particulate

- Filtration element

- membrane

Description

TYPE OF EQUIPMENT:

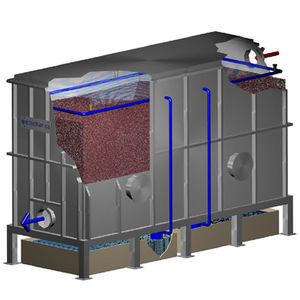

Compact Biofilter.

OPERATING PRINCIPALS:

IThe ecochimica® biofilter is used to treat gaseous effluents. Air entering the biofilter travels upward through the bed/support (organic particulate material coated with an aqueous “biofilm” in which the micro-organisms are present) while the contaminants present in the air are stripped and metabolized.

The contaminants are then transformed into water vapour, carbon dioxide and biomass through biological oxidation with the oxygen present in the air.

Through the use of appropriate materials (compost, bark, wood chips, etc.) the filter bed can last for several years. Correct operation of the biofilter requires maintaining the following parameters: temperature (>10°C), pH (as close to neutral as possible), humidity (to maintain the biofilm and hence the population of microbes) as well as nutrients and oxygen.

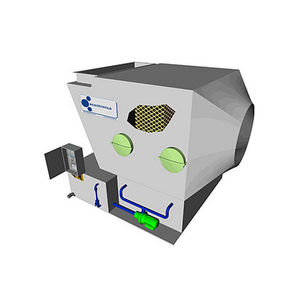

The humidity can be maintained through an ecochimica TW® scrubber/humidifier which not only saturates the air entering the biofilter (creating the optimal conditions) but also can be used as a pre-treatment stage to remove any contaminants which could damage the biofilter if they come into contact with it. Using an integrated scrubber-biofilter in series assures ideal operating conditions as air exiting the scrubber is saturated with humidity.

For this purpose, where a chemical pre-treatment is not necessary ecochimica® can supply UHR® series humidifiers which are less expensive than the TW® scrubber but equally effective in humidifying the air.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.