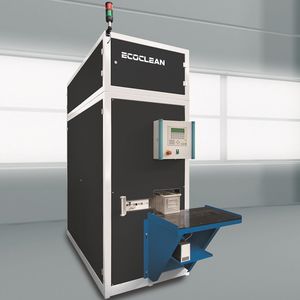

Ultrasonic cleaning system EcoCedgesprayimmersionautomatic

Add to favorites

Compare this product

Characteristics

- Technology

- ultrasonic, spray, immersion

- Operational mode

- automatic

- Applications

- industrial, process, parts

Description

The powerful start to aqueous parts cleaning

The EcoCedge is a powerful spray flood cleaning system with a vacuum-tight working chamber, which can be used for a very wide variety of industrial parts cleaning applications. Depending on the features installed the system is suitable not only for removing oil and emulsion from mass-produced parts but also for the fine cleaning of assembly parts. All the cleaning stages use an immersion process and aqueous media.

Removal of large quantities of swarf from mass-produced parts and particles of dirt with a defined size in fine cleaning can be achieved by selecting the appropriate filtering system and other application-dependent optional extras such as ultrasonic cleaning. Thanks to cross contamination reduction a long bath life is already achieved in the basic version.

With its versatility in application, its minimized floorspace needs as well as reduced per-unit costs and stable process quality, the EcoCedge adds to a successful performance in your production.

Equipment and process

Cleaning and drying process in a vacuum-proof work chamber with sight glass

Work chamber is fed from the front

Automatic work chamber door locking

Rotation and oscillation movements to support the cleaning and drying effect

Integrated full-flow filtration

Integrated oil separator

Siemens S7 PLC control system for custom programming of process sequences

Closed system housing with integrated floor tray

Optional packages and additional features

Machine roof incl. aspiration of machine interior

Vacuum drying

Third flood tank for additional rinsing

Cartridge filter for fine cleaning

Catalogs

No catalogs are available for this product.

See all of Ecoclean Group‘s catalogsRelated Searches

- Automatic washing machine

- Water washing machine

- Industrial washing machine

- Ultrasonic cleaning system

- Process washing machine

- Spray washing machine

- Parts washing machine

- Solvent washing machine

- Compact washing machine

- Washing machine with rinsing

- Immersion cleaning system

- Washing machine with dryer

- Degreasing washing machine

- Surface treatment cleaning system

- Eco-friendly washing machine

- Custom washing machine

- High-pressure washing machine

- Continuous washing machine

- Environmentally friendly washing machine

- Electronic cleaning system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.