- Machine-tools

- Cutting Tool

- Internal burnishing tool

- Ecoroll Tool Technology

- Products

- Catalogs

- News & Trends

- Exhibitions

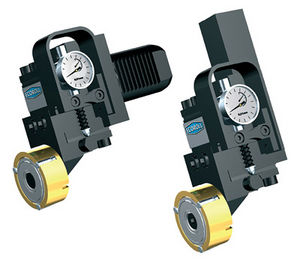

Internal burnishing tool 1µm, HRC max. 45 | EG90external

Add to favorites

Compare this product

Characteristics

- Options

- internal, external

Description

Machining of all symmetrically rotating, straight surfaces as well cylinders, external tapers and internal cones.

Attainable surface finish Rz < 1 micron.

Processing of all metallic materials with a maximum hardness of HRC = 45.

Complete processing in one setting.

Short primary processing time.

For use with either CNC-controlled or conventional lathes.

A special advantage is the overhung layout of the roller in feeding direction, allowing a treating of the work piece close to the shoulders of adjacent faces.

Tool consists mainly of tool body equipped with a spring assembly that allows the roller head to move with no play and very low friction.

Additional parts of tool body: Tension rod, tool holder, connection, leaf springs, roller head, roller holder, dial gauge.

Special version: Position sensor.

Catalogs

No catalogs are available for this product.

See all of Ecoroll Tool Technology‘s catalogsOther Ecoroll Tool Technology products

Single-roller Mechanical Tools

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.