- Machine-tools

- Cutting Tool

- Burnishing tool

- Ecoroll Tool Technology

- Products

- Catalogs

- News & Trends

- Exhibitions

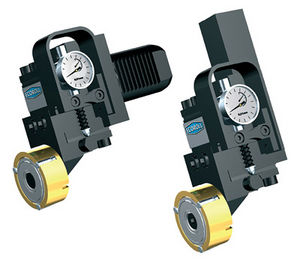

Burnishing tool 20 - 35 kN, 1400 N/mm2, min. ø80 mm | FAKxxx series

Add to favorites

Compare this product

Description

Deep rolls fillets with the plunge-in process.

Deep rolls contours or large fillets with the in-feed process.

Roller unit includes axial/radial bearings for the in-feed process.

Rolling force monitored by a dial gauge or sensor.

For use with CNC-controlled or conventional lathes.

Complete processing in one setting.

Symmetrical construction allows either right- or left-hand operation.

Rotates in either direction.

Type FAK deep rolling tools consist of a tool body equipped with a shank, a spring assembly that allows the roller head to move with no play and very low friction, and a dial gauge that indicates the burnishing force as measured by spring deflection.

An optional device transmits the values by cable or wireless signal to an external indicator.

The roller head is attached to the flexible, spring-loaded section of the tool body.

The flexible roller holder moves in response to the radial or axial rolling forces on either side of the tool. The roller holder contains a finely machined, hardened roller with two tapered roller bearings.

Catalogs

No catalogs are available for this product.

See all of Ecoroll Tool Technology‘s catalogsOther Ecoroll Tool Technology products

Single-roller Mechanical Tools

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.