- Machine-tools

- Cutting Tool

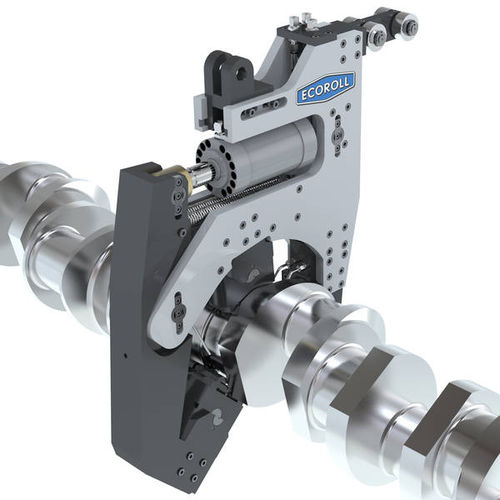

- External rolling head

- Ecoroll Tool Technology

- Products

- Catalogs

- News & Trends

- Exhibitions

External rolling head HRC max. 45, max. 1200 N/mm2

Add to favorites

Compare this product

Characteristics

- Options

- external

Description

Simultaneous deep rolling of two large radii on main bearings and crank pin bearings of crankshafts.

ECOROLL’s multiple roller deep rolling tool HFK02 exp. (expanding) is specially designed to deep roll two large radii on main bearings and crank pin bearings on crankshafts in the same process. Deep rolling results in a considerable increase in fatigue strength, i.e. in the amount of load alternations possible without the work piece suffering fatigue or fracture. Deep rolling offers a unique combination of three physical effects to achieve this result:

- Generating compressive stresses in the edge zone with deep penetration

- Cold working to increase strength

- Eliminating micro-notches by smoothing the surface

All ductile metals up to a hardness of 45 HRC with a tensile strength up to 1400 N/mm² or a yield strength of 1200 N/mm² can be deep rolled. A hydraulic cylinder is used to apply the required deep rolling force. The maximum load for the hydraulic cylinder is 250 bar.

The deep rolling tool HFK02 exp. is characterized by its force-locking design, i.e. no deep rolling forces are conducted into the machine. Due to its C-shaped design, the forces remain in the tool.

The dimension X refers to the cylinder in the retracted position which is greater than the processing diameter so that the tool can run in upon set-up without collision. The diameters to be machined can be of various designs. To process different diameters, the roller heads come in various sizes and must be exchanged. The roller heads are set for specific processing diameters. In addition, the roller heads also determine the width of the bearing seat to be processed.

Catalogs

No catalogs are available for this product.

See all of Ecoroll Tool Technology‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.