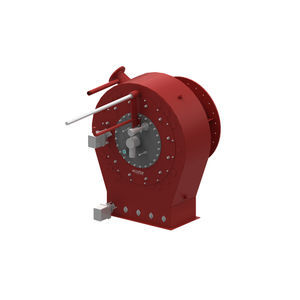

Nozzle mix burner GRM serieschamberlight fuel oilnatural gas

Add to favorites

Compare this product

Characteristics

- Type

- nozzle mix, chamber

- Power source

- light fuel oil, natural gas

- Firing

- direct fired

- Applications

- heating, food

- Head length

- standard

- Power

Min.: 174.4 kW

Max.: 1,162.7 kW

Description

GAZORAM burners are nozzle-mixed burners and used in industrial direct-heating furnaces and drying applications. These furnaces usually have a balanced pressure in the combustion chamber and require burners with wide operating ranges. GAZORAM burners have a simple operating logic and easily adapt to many applications with different installation options. Gazoram burners operate at gas pressure of 21 to 50 mbar.

SPECIFICATIONS

Operation in wide modulation range

7 different capacity options in the range of 5-1160 kW

Operation with Natural gas and LPG

Flame control with ionization or photocell (optional)

Easy assembly and disassembly thanks to its design

Easy operation and maintenance

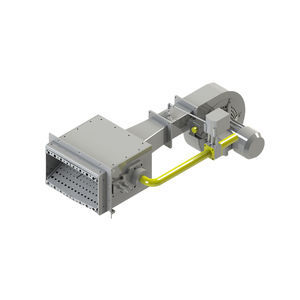

AREAS OF USE

Textile machinery

Printing machines

Drying and hardening furnaces

Combustion furnaces

Indirect air heating

Textile drying

Food processing/cooking

Tempering

Aluminum homogenization

Conversion of ram-dryers working with hot oil and steam

STANDARD EQUIPMENT

Electromagnetic safety and operating valve: An electromagnetic valve that ensures fully safe operation of the burner.

Servo motor air/fuel adjustment: Precise air-fuel adjustment is provided by mechanically modulating klappes.

Control Relay: Provides safe combustion control.

Gas Pressure Switch: The gas pressure switch on the operating valve controls the gas pressure and prevents any problems that may occur due to pressure drops in the system.

Air Pressure Switch: Ensures safety by checking for the availability of minimum combustion air required for safe combustion.

Catalogs

grm series burners 2017

8 Pages

Gazoram Drying Burners

8 Pages

Related Searches

- Gas burner

- Direct fired burner

- Hot water boiler

- Gas boiler

- Natural gas burner

- Nozzle mix burner

- Indirectly fired burner

- Heaters burner

- Fuel oil burner

- Compact boiler

- Natural gas boiler

- Standard burner

- Boiler burner

- Monobloc burner

- Low-emission burner

- Pilot burner

- Condensing boiler

- Furnace burner

- Low-emission boiler

- Modular burner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.