- Industrial machines and equipment

- Mixing and Dosing

- Dynamic mixer

- Eirich Industrial Ltda

- Products

- Catalogs

- News & Trends

- Exhibitions

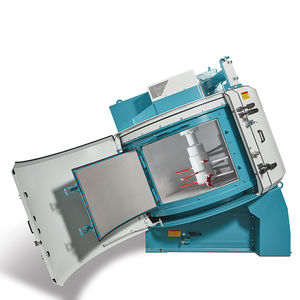

Dynamic mixer R24continuousvertical

Add to favorites

Compare this product

Characteristics

- Technology

- dynamic

- Batch/continuous

- continuous

- Configuration

- vertical

Description

The Eirich Intensive Mixer is a synonym for optimum Mixing Technology.

Eirich Intensive Mixers of the Type R Series were developed for the most diverse jobs in the processing of raw materials, mechanical mixtures and compounds. Variable setting of machine components and the energy range ensures a high degree of efficiency.

Three components determine the characteristics of these mixers:

An inclined, rotating mixing pan: a rotating mixing pan that continually transports the material to the rotating mixing tool, inducing counter-flowing currents of material with a high velocity differential.

An inclined rotating mixing pan, which together with a stationary multi-purpose wall bottom scraper produces high vertical flowrates.

An adjustable multi-purpose wall-bottom scraper designed to prevent residue accumulations on the walls and bottom surface of the mixing pan and to accelerate material discharge at the end of the mixing cycle.

The advantages resulting for the user are considerable:

Optimum homogenization of the process material

Shortest mixing times

Little wear

Low-maintenance design

Excellent, constant quality of process material (permanently)

Continuous or batch wise mode of operation

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.