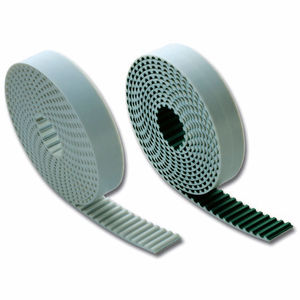

Flat belt ELAClean® seriestoothedpolyurethanethermoplastic

Add to favorites

Compare this product

Characteristics

- Type

- flat, toothed

- Material

- polyurethane, thermoplastic

- Product applications

- for food

- Sector

- industrial

- Other characteristics

- high-performance, smooth

- Length

Max.: 100 mm

(3.94 in)Min.: 60 mm

(2.36 in)- Width

Max.: 1,800 mm

(70.866 in)Min.: 1,524 mm

(60 in)- Thickness

Max.: 10.5 mm

(0.41 in)Min.: 3 mm

(0.12 in)- Pitch

Max.: 50 mm

(1.969 in)Min.: 26 mm

(1.024 in)- Temperature

Max.: 80 °C

(176 °F)Min.: -30 °C

(-22 °F)

Description

ELAClean® belts are a new range of monolithic belts made of homogeneous, thermoplastic polyurethane, specifically designed for food contact and suitable to meet the required hygiene standards. They are available in various profiles and surface finishing, ensuring quality, precision and customizations for a wide range of applications.

All ELAClean® belts can withstand oil, grease, cleaning agents, bacteria, making them exceptionally easy to clean and suitable in critical hygiene applications (e. g. when processing meat, poultry or seafood, dough and fresh dairy products). In addition to those benefits, ELAClean® belts can be also customized (e. g. with profiles, flights and sidewalls) to handle a wide range of conveying jobs.

ELAClean® meets the requirements of the food industry in terms of efficiency, safety, and compliance with regulatory standards, offering:

Reduced downtime for maintenance and replacement thanks to the high-performance polyurethane that minimizes the risk of belt failure due to tear and wear;

Easy cleaning, maintenance and increased overall hygiene of the food production environment, thanks to the smooth and seamless surface;

Durability and reliability of conveying surface that ensuring an efficient flow of materials throughout the production line.

ELAClean® range includes Positive drive belts [tooth pitch 26mm (EC-P1) and 50mm (EC-P2, Self centering positive drive belt [tooth pitch: 39.7mm (EC-C4 and Flat belts [belt thickness: 3mm (EC-F3. Each one of these can be provided with specific surface finishing, according to different application needs.

Catalogs

No catalogs are available for this product.

See all of Elatech S.r.l.‘s catalogsRelated Searches

- Elatech transmission belt

- Elatech industrial belt

- Rubber power transmission belt

- Elatech plastic belt

- Timing belt

- Industrial belt

- Sturdy belt

- Elatech polyurethane belt

- Elatech synchronous belt

- Flat strip

- Oil-resistant power transmission belt

- Flexible belt

- High-performance power transmission belt

- High-resistance power transmission belt

- Abrasion-resistant strip

- Endless power transmission belt

- Machine power transmission belt

- Maintenance-free power transmission belt

- Belt for the textile industry

- Machine tool power transmission belt

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.