- Production Machines

- Cutting Machine

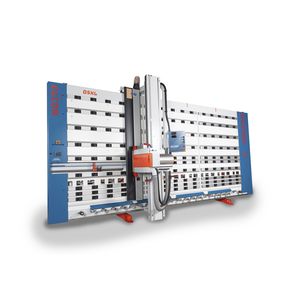

- Panel saw

- Elcon Sawing Technology

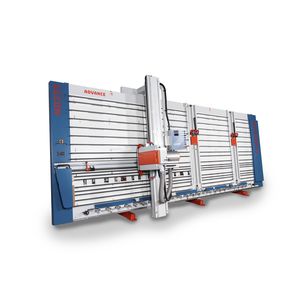

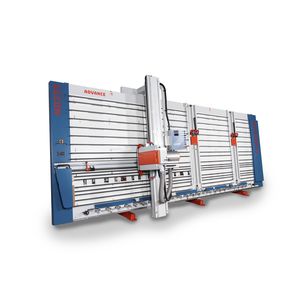

Panel saw ADVANCEhorizontalverticalfor aluminum

Add to favorites

Compare this product

Characteristics

- Technology

- panel

- Orientation

- horizontal, vertical

- Treated material

- for aluminum, wood, for composites

- Operational mode

- manual actuation

- Circular saw blade diameter

300 mm

(12 in)

Description

The ADVANCE range makes cutting panels to size very easy, without the need for manipulation, turning or stocking of strips in between horizontal and vertical cuts. Moreover it offers the possibility to trim the bottom of (multiple) panels.

-Characteristics

Advance clamping system for horizontal and vertical cutting to size in one course

Lifting of the panels for the bottom reference cut and for strip cutting from the bottom, allowing strips to be cut to size without taking them of the machine and bringing them back on for temporary stocking in between.

-Automatic shifting backframe

To prevent damaging the support strip when cutting horizontally, the backframe is automatically lifted when the saw blade is at the height of one of the strips.

-Clip board for job cards

Handy holder of operator information or documents at the side of the control box.

-Cutting depth 80 mm

Maximum thickness of the material: 80 mm

-Double bearing bottom rollers, with pneumatic panel clamp and panel turn over possibility

For transport of heavy panels or a package of panels simultaneously, every meter-section 5 aluminium rollers are provided. A pneumatic clamp, that can be activated from the control panel, prevents that panels on the transportrollers move while cutting. In this way also light and thin panels can be cut accurately.In order to rotate bigger panels, the distance between 2 of the bottom rollers is chosen such that a panel can be turned very easily.

-Entry and exit rollers for panel handling

Left- and right-side entry and exit rollers for easy panel handling.

-Failure diagnosis

Location of possible failures by easy accesible LED display

Catalogs

Related Searches

- Metal sawing machine

- Automatic sawing machine

- Wood sawing machine

- Horizontal sawing machine

- Profile sawing machine

- Precision sawing machine

- Aluminum sawing machine

- Plastic sawing machine

- Vertical sawing machine

- Compact sawing machine

- Panel sawing machine

- Programmable saw

- Manual actuation saw

- Composite saw

- Beam sawing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.