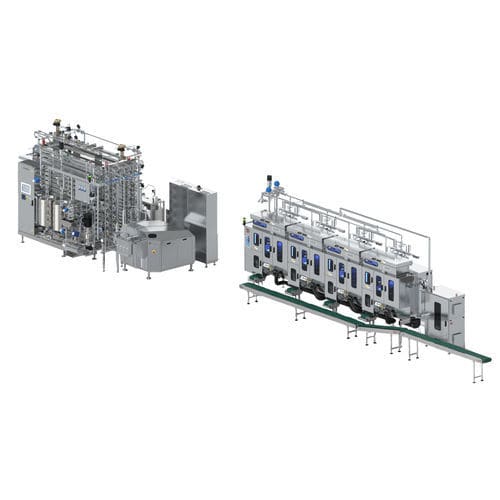

Elecster offers a turnkey solution for UHT milk processing and packaging. Thanks to a wide range of capacity options, we are able to customize the right size UHT line according to the customer’s requirements, starting from 800 liters per hour up to 10,000 liters per hour. If the need for capacity is even greater, Elecster UHT lines can be integrated with each other. This means that the capacity of Elecster UHT lines is expandable and therefore it is almost limitless. This advantage allows you to start UHT milk production at just the capacity you want. Thanks to the integration option, you can easily add more processing capacity or packaging capacity to your existing UHT line, without having to upgrade the entire equipment. The Elecster solution is suitable for both beginners and those already in the field.

As a turn-key solution supplier, Elecster provides complete UHT milk processing and packaging lines, packaging material, downstream equipment and aftersales services.

Our technology means reliability and responsibility.

Compact system with optimized capacities. Elecster processing and packaging machines are tailored to work as a complete line. This is a guarantee for high performance and production efficiency. No need for expensive aseptic buffer tank or separate CIP system, which makes Elecster complete UHT line a cost efficient and space saving solution.

Elecster equipment is designed, assembled and tested in Finland. Test runs are performed on the entire UHT line at the Elecster factory. For this reason, the installation and commissioning of the line is effortless and fast.