- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Chamber furnace polymerizationforced convectionindustrial

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- polymerization

- Atmosphere

- forced convection

- Other characteristics

- industrial

Description

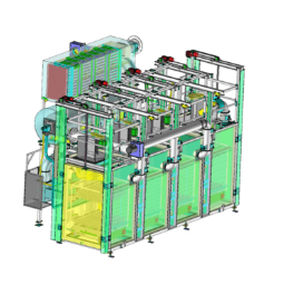

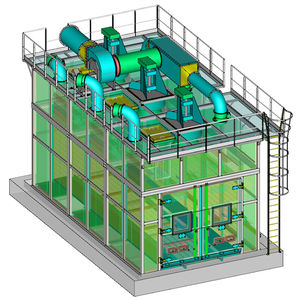

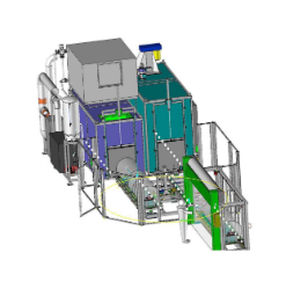

Batch oven for polymerization and forming. Industrial oven with convected air

Our batch ovens are suitable for all industrial processes such as preheating, drying, curing, polymerization, vulcanization, annealing, cooling etc.

Based on a very robust, continuously welded structure frame with a tight internal lab that meet the requirements of processes with solvants. Specific studies enable to calculate the quantity of fresh air to enable the ideal exhaust of solvants in order to comply to norms about explositivity risks.

All types of heat sources are available: gas-fired with or without heat exchanger; electrically heated ; water-steam-oil battery heated; uniform air distribution: for each project, the best air flow type is chosen based on the product configuration. With possibilities of top-down, bottom-up, top-bottom, longitudinal or multi-flow we assure the oven to have the required temperature uniformity. All batch ovens are assembled, wired and tested in our workshop including the supply of temperature test curves. Isotherm, ventilated air volumes and the heating power are specifically defined according the thermprocess. Standard isotherm: for max. 300 °C, +/- 5 °C.

Customized access solutions according the loading and unloading procedures. One leaf or double leaf doors. Motorized sliding door. Cover that can be opened from the top for loading/ unloading . Motorized drawer system. Roller hearth furnaces. Bell type furnaces.

VIDEO

Catalogs

No catalogs are available for this product.

See all of ELMETHERM‘s catalogsRelated Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Combustion furnace

- Gas furnace

- Stainless steel furnace

- Tunnel furnace

- Baking oven

- Industrial furnace

- Automatic furnace

- Vacuum furnace

- Annealing furnace

- Continuous furnace

- Forced convection furnace

- Programmable furnace

- Thermal furnace

- Compact furnace

- Vertical furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.