- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

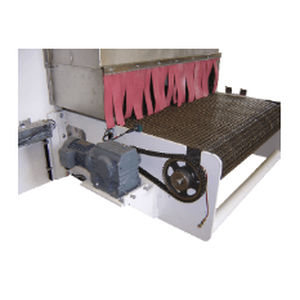

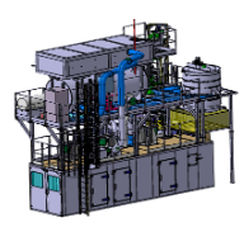

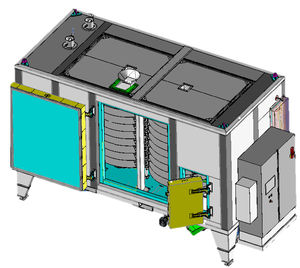

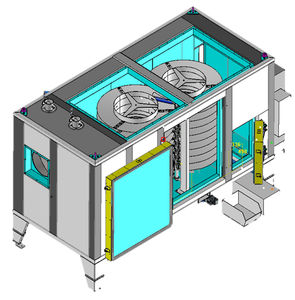

Conveyor oven electriccontinuouscustom

Add to favorites

Compare this product

Characteristics

- Configuration

- conveyor

- Heat source

- electric

- Other characteristics

- continuous, custom, automatic

Description

Our custom conveyor ovens can provide temperature controls in multiple zones according to the different stages of the heating process of your product (desolvatation, temperature ramp, dwell time, cooling).

Every zone has its own temperature management and its own extraction. Based on perfect knowledge of the products and a continuous control of the solvants evaporated, the extractions are optimized and the heating power adapted responding to security norms and excluding explosive risks.

The fumes can be send to an incinerator to eliminate VOC or to a heat exchanger to recover energy.

As your product has unique features, the way it is heated will ensure process performance and a maximum of isotherm.

The velocity and the orientation of the air flows are specific to each product. ELMETHERM offers the most suitable air flow styles (top to bottom, bottom to top, Transversal, Longitudinal, counter flow, multi flow.).

The appropriately located pressure plenums will lead the air to the product through nozzles or adjustable whole area of heating and ensuring good temperature uniformity throughout the cycle.

VIDEO

Catalogs

No catalogs are available for this product.

See all of ELMETHERM‘s catalogsRelated Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Combustion furnace

- Gas furnace

- Stainless steel furnace

- Tunnel furnace

- Baking oven

- Industrial furnace

- Automatic furnace

- Vacuum furnace

- Continuous furnace

- Annealing furnace

- Forced convection furnace

- Programmable furnace

- Thermal furnace

- Compact furnace

- Vertical furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.