- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Rotary furnace heat treatmentelectricforced convection

Add to favorites

Compare this product

Characteristics

- Configuration

- rotary

- Function

- heat treatment

- Heat source

- electric

- Atmosphere

- forced convection

- Other characteristics

- continuous, industrial

- Maximum temperature

300 °C

(572 °F)

Description

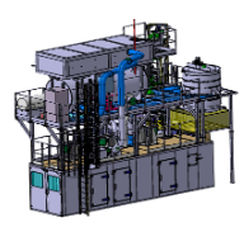

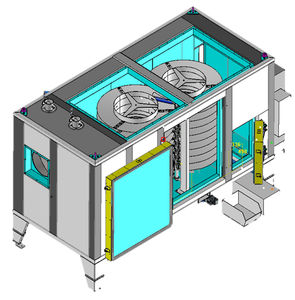

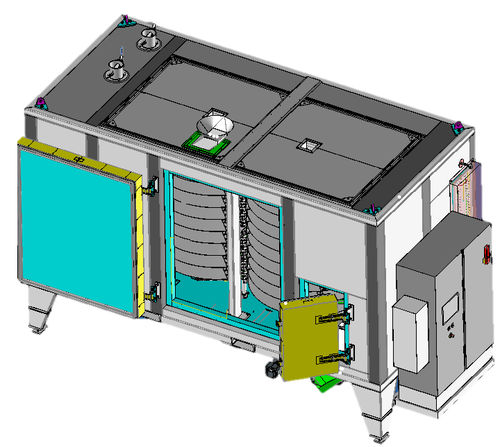

Double drum oven:

Bulk parts are conveyed through the heating zone by a drum conveyor that rotates on several levels.

The workpieces circulate in a continuous flow and arrive - through a funnel - on a drum conveyor, which transports the workpieces into the hot zone in a continuous clockwise rotating movement. The workpieces are transferred between the different levels of the two drum conveyors, which rotate clockwise and counterclockwise. The parts arriving at the last level are conveyed via a funnel into the unloading area.

The advantages:

Furnace with the advantages of a horizontal conveyor furnace (continuous process);

Low floor space requirement;

Easily integrated into a continuous line.

Numerous industrial applications.

Catalogs

No catalogs are available for this product.

See all of ELMETHERM‘s catalogsRelated Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Combustion furnace

- Gas furnace

- Stainless steel furnace

- Tunnel furnace

- Baking oven

- Industrial furnace

- Automatic furnace

- Vacuum furnace

- Continuous furnace

- Annealing furnace

- Forced convection furnace

- Programmable furnace

- Thermal furnace

- Compact furnace

- Vertical furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.