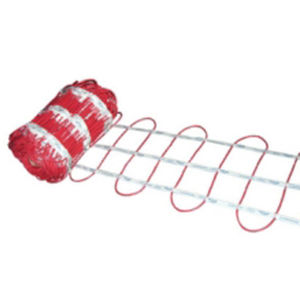

Self-regulating heating cable fluoropolymer-insulatedthermoplastic-insulated

Add to favorites

Compare this product

Characteristics

- Sheathing / insulating material

- fluoropolymer-insulated, thermoplastic-insulated

- Type

- self-regulating

Description

Self-regulating heating cables are used for the temperature maintenance of pipes, tanks, pumps etc.; furthermore they are used in order to avoid ice formation on ramps, streets, stairs, drainpipes, roofs etc.

Self-regulating cables are heating cables with semi-conductive matrix made from a graphite and polymer dust mixture extruded on two conductors of a suitable section; this matrix is successively irradiated in order to fix the molecular structure and to make a memory of his starting construction.

Then it is covered with a thermoplastic material and with a further fluoropolymer protection. Or thermoplastic material.

In this way the basic cable has been assembled. This cable can be then covered with a tinned copped or stainless steel shield for mechanical protection and ground cable and lastly from a fluoropolymer protection or thermoplastic material.

During the manufacturing the graphite molecules tend to connect among themselves and to build chains that are casually organized inside the matrix. These chains are conductive.

When the two conductors are powered on one extremity and insulated on the opposite part of the cable, the electricity supply goes through these micro-heaters and produces some heat. When the heating cable’s temperature increases (for both the produced power and for the external temperature), the polymer molecules expand themselves and can break the graphite chains, reducing the heat quantity produced in the microcircuits.

Catalogs

No catalogs are available for this product.

See all of ELMITI‘s catalogsRelated Searches

- Resistance heater

- Immersion heater

- Tubular resistance heater

- Cartridge heater

- Drum heater

- Heating cable

- Flat resistance heater

- Band heater

- Ceramic resistance heater

- Industrial resistance heater

- Stainless steel resistance heater

- Electric band heater

- Aluminum resistance heater

- Resistance heater with thermostat

- Tubular cartridge heater

- Finned resistance heater

- Belt drum heater

- Stainless steel immersion heater

- 230 V cartridge heater

- Flange immersion heater

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.