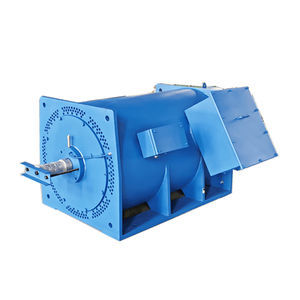

Motor with slip ring-wound rotor YRKSasynchronous> 1000 VIP55

Add to favorites

Compare this product

Characteristics

- Type

- asynchronous

- Voltage

- > 1000 V

- Protection class

- IP55, IP54, IP56, IP23, IP24

- Configuration

- with slip ring-wound rotor

- Efficiency classes

- IE2, IE3, IE4, IE5

- Number of poles

- 4-pole, 6-pole, 8-pole, 16-pole

- Cooling mechanism

- air-cooled, water-cooled

- Applications

- for pump, blower, for conveyors, for compressors, for the mining industry, for crusher

- Other characteristics

- variable-speed, high-voltage, high-efficiency, high-torque, low-noise, inverter duty, constant speed, NEMA, UL certified

- Power

Max.: 10,000 kW

(13,596.212 hp)Min.: 160 kW

(217.539 hp)

Description

YRKS wound rotor slip ring high voltage motors with carbon brush mainly used in applications requiring high starting torque or low starting current such as ball mill, steel rolling mill, paper mill and cement mill. they also can be produce inverter duty.

Frame Including: 315,355,400,450,500,560,630,710,800,900,1120

Cooling method: IC01,IC06,IC411, IC416, IC511, IC516, IC611, IC616, IC666, IC81W, IC86W, IC37

Mounting type: IMB3, IMB35, IMV1,IM7311

Color: blue or as requirement

Insulation class: F or H

Temperature rise: B or F

Accessory: PT100, PTC, PTO, Space heater, SPM vibration sensors

YRKS wound rotor high voltage slip ring motor with carbon brush are used in applications requiring high starting torque or low starting current. These motors provide maximum availability, and are especially recommended for heavy load inertia applications like mill drives or situations where network conditions are weak. Slip-ring motors are of modular construction and have a wide range of accessories. Depending on the application many alternative cooling and enclosure types are available.

YRKS motors have a welded steel frame. Slip ring unit can be supplied with permanent contact brushes, or with brush lifting gear. In both cases the slip rings are enclosed in a housing located at the N-end and separated from the main motor frame. Liquid resistance starter(LRS) is available on request. For YRKS motors this catalog only shows the typical technical data of 6kV and 10kV at 50 Hz for 4, 6, and 8 pole motors. While the complete product scope covers motors with 60Hz, pole numbers up to 16, and voltage rating up to 13.8kV.

Catalogs

No catalogs are available for this product.

See all of Elom Motor‘s catalogsRelated Searches

- Electromotor

- Vehicle motor

- AC motor

- Synchronous motor

- Induction motor

- Multipole motor

- 3-phase motor

- Motor for industrial applications

- 4-pole electromotor

- IP55 motor

- 2-pole motor

- High-efficiency electromotor

- Ultra-compact motor

- Permanent magnet motor

- Protection level motor

- Pump motor

- 6-pole motor

- High-torque motor

- IP54 motor

- Low-voltage motor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.