- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Immersion heater

- ElringKlinger Kunststofftechnik

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

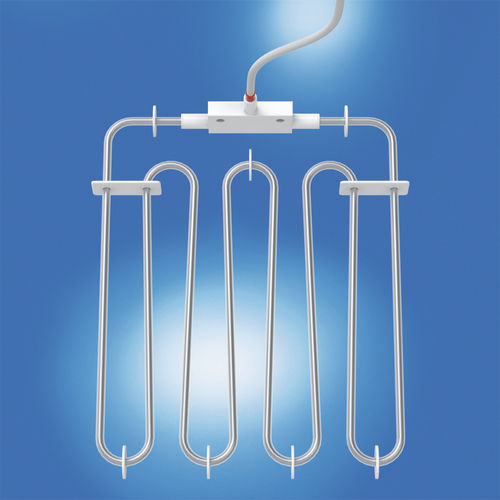

Immersion heater

Add to favorites

Compare this product

Description

ElringKlinger Engineered Plastics immersion heaters consist of a stainless steel heating

element encapsulated with a MoldflonTM-PFA tube using a unique process which minimizes air inclusion and improves thermal efficiency. The connecting harness consists of electrical cables which are wrapped together with a PTFE film and then shrouded in a PolytetraflonTM-PTFE outer shell which can be hermetically sealed to the tank using a suitable bulk-head fitting. The combination of materials used provide a thermally stable interconnecting system suitable for use in a wide range of applications and process temperatures.

The heater head is machined from solid PolytetraflonTM-PTFE without any mechanical connections. The heater tubes and connecting harness are welded in place to ensure a fluid tight connection which can be fully immersed in the process fluid.

Because of the simple head design, numerous options for securing the immersion heater are available which allows each unit to be ideally positioned in the tank. For added protection and safety, most immersion heaters are available with the option of thermal overload protection.

Catalogs

No catalogs are available for this product.

See all of ElringKlinger Kunststofftechnik‘s catalogsRelated Searches

- Heat exchanger unit

- Liquid/liquid heat exchanger

- Plate heat exchanger unit

- Tubular heat exchanger

- Industrial heat exchanger unit

- Compact heat exchanger unit

- Immersion heater

- Shell and tube heat exchanger

- Heat exchanger for the food industry

- High-performance heat exchanger

- Heat exchanger for the chemical industry

- Technology heat exchanger

- Heat exchanger for the pharmaceutical industry

- Corrosion-resistant heat exchanger

- Refrigeration heat exchanger

- Custom heat exchanger

- Heat exchanger for the petrochemical industry

- Heat exchanger for the automotive industry

- High-temperature heat exchanger

- Surface heat exchanger

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.