Chamber oven dryingcuring

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- drying, curing

Description

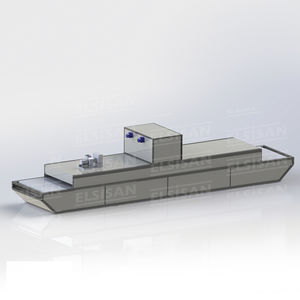

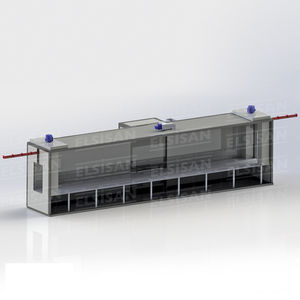

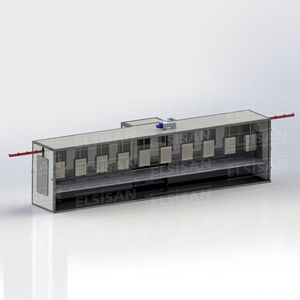

Dip type ovens are drying ovens used at the end process of surface pretreatment lines. The products whose surface treatment is completed are dipped in these ovens for drying. Ovens are designed to have a place for one or more baskets depending on capacity. In processes that require very high capacities or long curing time, dip type ovens with internal conveyors are made. The materials enter into the oven from the entrance station move step by step towards the exit door and complete the processing time. Then unload by robotic crane. Oven temperatures can be controlled and adjusted with PLC system panel.

Catalogs

No catalogs are available for this product.

See all of Elsisan‘s catalogsRelated Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Combustion furnace

- Gas furnace

- Stainless steel furnace

- Tunnel furnace

- Baking oven

- Industrial furnace

- Digital furnace

- Programmable furnace

- Air circulating furnace

- Conveyor furnace

- Custom furnace

- Preheating furnace

- Aluminum furnace

- Steel furnace

- Infrared furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.