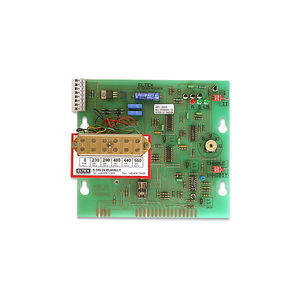

Sensor module ANTI

Add to favorites

Compare this product

Description

ELTEX weft sensor ANTI-2

with logic current output

General description

The ANTI-2 weft break sensor is working on the piezoelectric principle. The yarn movement is

transferred into an electrical signal, which is amplified and evaluated within the sensor. The

weft sensor has a logic current output and is manufactured with 8 eyelets.

A green light emitting diode indicates when a yarn is moving. The ANTI-2 weft sensor will detect if a second weft is inserted by mistake. A red light emitting diode on the sensor will indicate if the machine has stopped because too many weft yarns were inserted.

Function and description

Eyelet diameter: 7 mm

Power supply: 24 V DC (16–28 V DC)

Current consumption: 50 mA

Sensitivity setting is made through a DC voltage 0–6.5 V, normally from the central control unit. Some models have a potentiometer for the sensitivity setting. The movement of the yarn is best detected if the yarn angle is 10–15° through the eyelet.

Output: The weft sensor will send one current unit as output if one weft yarn is moving. If the weft sensor finds two eyelets with moving yarns, this will result in two current units on the output

To be able to detect if an extra weft yarn is inserted even if this extra yarn is dropped during the insertion, it is necessary to have two sensing periods. The first sensing period will be before the transfer point and the second at the very end of the yarn insertion.

The ANTI-2 weft sensor is scanning the eyelets to find if two wefts are moving. Therefore it is advisable to start the first sensing period at least 35 ms after the weft insertion has started.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.