- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

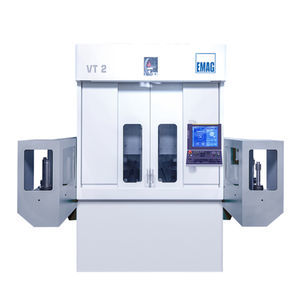

CNC turning machine VLC 100vertical3-axis12 tools

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- vertical

- Number of axes

- 3-axis

- Number of tool stations

- 12 tools

- Applications

- drilling

- Associated function

- milling, grinding

- Diameter

160 mm

(6.3 in)- Part diameter

100 mm

(4 in)- Maximum part length

150 mm

(6 in)- Axe X

650 mm

(26 in)- Axe Z

375 mm

(15 in)

Description

The VLC 100 is a CNC turning machine with a modular structure that allows it to be configured for a wide variety of applications. Whether turning, grinding, milling, gear hobbing, or induction hardening — the CNC lathe can be flexibly equipped with virtually all the technologies of the EMAG Group.

The VLC 100 is the ideal CNC turning center for producing chucked parts up to 100 mm in diameter. The modular VL 2 machine already offers a wide range of configuration options, but with the VLC 100 there are essentially no limits to what the user can do. Technologies from the full portfolio of the EMAG Group can be installed on the VLC 100, making it one of the most versatile vertical CNC turning machines in the EMAG machine catalog. The VLC 100 is useful in any application where very high requirements are placed on the manufacture of parts.

Integrated pick-up automation system

The CNC turning machines in the VLC series are equipped with a pick-up spindle that loads parts from the integrated conveyor belt and feeds them into the machining area—the short distance makes for shorter chip-to-chip times. The machining area can be configured flexibly and the tool turret, with its twelve tool positions, can be equipped with driven tools and stationary tools for the turning process.

A few of the available technology modules

Out-of-round turning unit

Hard turning (block tool holder)

Combined hard turning + OD grinding

Combined hard turning + ID + OD grinding

Advantages

Machine can be customized to processing requirements

Wide range of technology modules available for selection

Ideally prepared to meet any customer requirements

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.