- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

CNC turning machine VL 4vertical3-axis12 tools

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- vertical

- Number of axes

- 3-axis

- Number of tool stations

- 12 tools

- Performance

- powerful

- Other characteristics

- compact

- Diameter

260 mm

(10.24 in)- Spindle speed

4,500 rpm

(28,274.334 rad.min-1)- Part diameter

200 mm

(8 in)- Maximum part length

200 mm

(8 in)- Axe X

760 mm

(30 in)- Axe Z

415 mm

(16 in)- Rapids on X

60,000 mm/min

(39 in/s)- Rapids on Z

30,000 mm/min

(20 in/s)- Nominal power

18 kW, 25 kW

(24.5 hp, 34 hp)- Maximum torque

202 Nm, 280 Nm

(149 ft.lb, 207 ft.lb)

Description

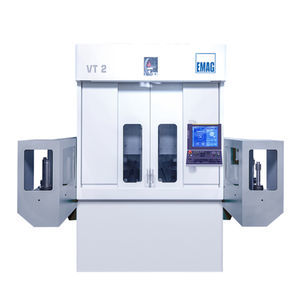

The VL 4 vertical turning center is able to machine workpieces having a maximum diameter of up to 200 mm. The VL 4 is one of EMAG's modular turning centers that stand out by their very compact design. Like all vertical turning centers in this series, the VL 4 also features an integrated pick-up automation system.

Mass production manufacturing with the VL 4 vertical turning center

The modular concept of the VL 4 makes it possible: The vertical turning center perfectly adapts to various applications, features an extremely compact design and has powerful drives. The design of the VL 4 turning center allows for the flexible implementation of various manufacturing technologies for soft and hard machining.

The machine base made from MINERALIT® polymer concrete allows for low-vibration machining and ensures long tool life as well as very high machining quality when turning workpieces. The main spindle is fastened to the front side by means of a compound slide rest and enables dynamic motion along the X and Z-axes. A Y-axis for complex geometries is available as an option.

A 12-post tool turret, which stands out by its very short indexing times and outstanding stability, is used for the actual machining. Excellent accessibility of the machining area and tool turret allow for the vertical turning center to be retooled in a comparably short time.

A measuring station outside the machining area is available as an option for the vertical turning centers of the VL series. The measuring station is installed between the machining area and the pick-up station. Measuring is thus performed while loading/unloading, which saves considerable time.

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.