- Machine-tools

- Machining Center

- CNC lathe

- EMAG GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

CNC turning center VL 3 DUOvertical3-axis2-spindle

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- vertical

- Number of axes

- 3-axis

- Number of spindles

- 2-spindle

- Number of tool stations

- 12 tools

- Performance

- high-productivity

- Other characteristics

- compact

- Diameter

210 mm

(8.27 in)- Spindle speed

5,000 rpm

(31,415.927 rad.min-1)- Part diameter

150 mm

(6 in)- Maximum part length

110 mm

(4 in)- Axe X

505 mm

(20 in)- Axe Z

250 mm

(10 in)- Rapids on X

60,000 mm/min

(39 in/s)- Rapids on Z

30,000 mm/min

(20 in/s)- Nominal power

15.5 kW, 17.9 kW

(21.1 hp, 24.3 hp)- Maximum torque

98 Nm, 144 Nm

(72 ft.lb, 106 ft.lb)

Description

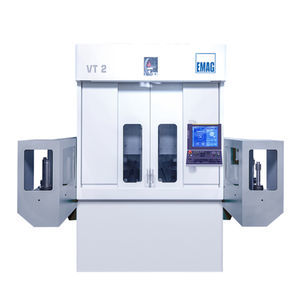

The EMAG VL 3 DUO CNC Machine, an efficient twin-spindle machine solution for chucked parts up to 150 mm in diameter, expands the product portfolio of the extremely successful VL series.

VL 3 DUO – Multi-Spindle Machines for High-Productive Manufacturing of Chucked Parts

The VL 3 DUO turning machines combine the technological developments of recent years, including pick-up automation and the TrackMotion automation system, to the modular basic design of the cnc machine – and creates an extremely efficient production system offering maximum productivity with minimal space requirements.

Like every EMAG modular turning machine, the VL 3 DUO multi-spindle machines are equipped with its own parts storage unit and a pick-up spindle for each work area.

The work areas are mirror images of each other, but each has their own working spindle. With output of up to 17.9 kW and torque up to 144 Nm, these spindles have the power for fast and precise cnc machining. Each work area features a tool turret with 12 tool positions, which can be loaded with driven tools as well as non-rotating lathe tools.

TrackMotion – Modern Parts Management in the Production Process

The EMAG TrackMotion automation system is an option on any VL 3 DUO turning lathe. This automation system consists of three central components: the track, the TransLift NC gripper moving along the track, and the storage unit for raw parts. The entire system is very compact and runs directly behind the work areas of the VL 3 DUO multi spindle machine. With the TrackMotion system, the individual workpiece is always the main focus.

VIDEO

Catalogs

VL-SERIES

16 Pages

Turning Machines - VL

16 Pages

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- High-precision turning center

- 12 tools turning center

- Milling machine

- High-rigidity turning center

- 3-axis turning center

- Compact CNC machining center

- 3-axis milling machine

- Vertical turning center

- High-productivity turning center

- Milling turning center

- Powerful turning center

- Compact turning center

- High-speed turning center

- Precision turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.