- Machine-tools

- Machining Center

- CNC lathe

- EMAG GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

CNC turning center VLC 400vertical3-axisfor large workpieces

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- vertical

- Number of axes

- 3-axis

- Applications

- for large workpieces

- Performance

- high-productivity, precision, high-rigidity

- Associated function

- milling, grinding, drilling

- Diameter

500 mm

(19.69 in)- Part diameter

400 mm

(16 in)- Maximum part length

300 mm

(12 in)- Axe X

995 mm

(39 in)- Axe Z

580 mm

(23 in)

Description

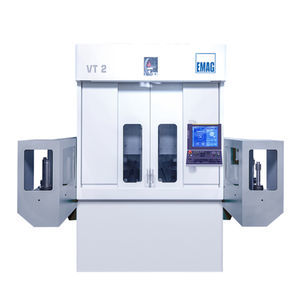

The VLC 400 is a vertical turning machine that offers great versatility for the manufacture of chucked parts thanks to its modular structure and the many technologies to choose from. It allows machining of chucked parts up to 400 mm in diameter.

The VLC 400 vertical pick-up turning machine gives the user nearly unlimited equipping options with machining technologies. Whether turning or milling, drilling or grinding – the user has access to the wide technology portfolio of the EMAG Group. This makes it possible to realize even complex manufacturing objectives using one or more machines from the VLC series. The largest machine in the VLC series, the VLC 400 is designed for chucked parts up to 400 mm in diameter.

The core of the VLC vertical turning machine is a base made from Mineralit® polymer concrete. It ensures low-vibration machining for long tool lifetimes and very high machining quality. High productivity and short chip-to-chip times are the result of the machine's top power combined with the pick-up function of the drive spindle. With this function the machine loads itself, taking parts from the integrated conveyor belt (likewise fully configurable) and feeding them into the machining area.

The working spindles have an especially high rigidity: Short distances between bearings, high-precision separable bearings in a tandem-O-tandem arrangement, and support bearings at the spindle end permit turning processes with micrometer accuracy.

A measuring probe is also available, allowing an inspection process to be integrated into the machining sequence.

Catalogs

No catalogs are available for this product.

See all of EMAG GmbH & Co. KG‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- High-precision turning center

- 12 tools turning center

- Milling machine

- High-rigidity turning center

- 3-axis turning center

- Compact CNC machining center

- 3-axis milling machine

- Vertical turning center

- High-productivity turning center

- Powerful turning center

- Milling turning center

- Compact turning center

- High-speed turning center

- Precision turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.