- Machine-tools

- Finishing Machine

- Gear grinding machine

- EMAG GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Workpiece grinding machine GR 250for gearshigh-precision

Add to favorites

Compare this product

Characteristics

- Applications

- workpiece, for gears

- Other characteristics

- high-precision

Description

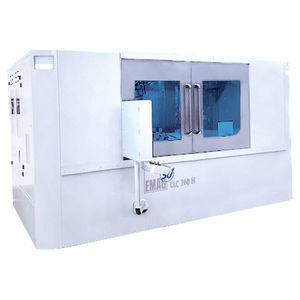

The latest innovation of EMAG SU is the GR 250, a screw profile grinding machine for worm screws with a maximum diameter of 250 mm and length up to 550 mm.

This grinding machine is equipped with a double table which eliminates downtimes almost completely.

Loading / unloading operations and measuring of components are performed in masked time. Since these operations do not affect cycle time, the entire lot productivity improves significantly. The changeover time is very fast, therefore the tool spindle works constantly on the workpiece.

The grinding machine GR 250 is equipped with Siemens Sinumerik 840D SL Numerical Control with an integrated operator panel and EMAG SU software, characterized by high-precision geometrical programming and an intuitive and user-friendly interface.

Furthermore, the EMAG SU GR 250 can easily interface with every type of automation. Particular attention has been paid to solutions which allow the reduction of changeover therefore considerably increasing the production speed and flexibility.

With EMAG SU machine tools is possible to grind different worms suitable for any worm gear sets according to client needs and specifications. There are many uses depending on the mechanical efficiency required by the industry and EMAG SU has the capability to grind the widest range of worms.

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Profile grinding

Profile grinding of gears and long, slim and toothed components is performed discontinuously, i.e., tooth gap by tooth gap, is completed one after the…

Catalogs

No catalogs are available for this product.

See all of EMAG GmbH & Co. KG‘s catalogsRelated Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Workpiece grinding machine

- Cylindrical grinding machine

- High-precision grinding machine

- Tool grinding machine

- External cylindrical grinding machine

- Vertical grinding machine

- Internal cylindrical grinding machine

- 3-axis grinding machine

- Universal grinding machine

- High-performance grinding machine

- High-productivity grinding machine

- High-speed grinding machine

- Gear grinding machine

- Horizontal grinding machine

- 2-axis grinding machine

- Compact grinding machine

- Large-size grinding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.