- Machine-tools

- Finishing Machine

- Gear grinding machine

- EMAG GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Workpiece grinding machine SG 160for gearsCNCwith linear motor

Add to favorites

Compare this product

Characteristics

- Applications

- workpiece, for gears

- Control type

- CNC

- Other characteristics

- with linear motor

Description

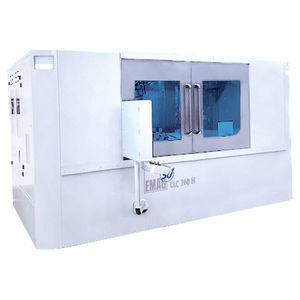

The SG 160 SKYGRIND is the first gear dry grinding machine in the world. It ensures cycle times for finishing of gears that are perfectly in line with the automotive industry at a lower cost compared to traditional manufacturing solutions.

First Gear Dry Grinding Machine in the World

The SG 160 SKYGRIND is the first gear dry grinding machine in the world. This state-of-the-art process eliminates the need for cooling oil during the hard finishing grinding of the toothed gear after the heat treatment.

On the SG 160 SKYGRIND machine the process is split in two main passes: roughing and finishing. For the roughing process skive hobbing is implied, whereas worm grinding is used for the finishing process. The SG 160 SKYGRIND removes about the 90% of the stock allowance with the first pass using a hobbing tool, which has the advantage of not heating the workpiece excessively. Subsequently, with the second finishing pass, a grinding wheel removes the remaining stock without causing problems of overheating the workpiece, therefore resulting in a completely dry process. Moreover, its innovative structure with two spindles actuated by linear motors and the use of more channels simultaneously ensure a time of chip-to-chip of less than 2 seconds.

The SG 160 SKYGRIND splits the X-axis of traditional machines into two linear slides (X1, X2), each of which carries tools spindles. In this way both workspindles are under full position control any time. Being driven by high dynamic 30 m/s linear motors, changing spindles come down to less than 2 seconds including simultaneous repositioning of the tools with the Y-Z-A axes.

Catalogs

No catalogs are available for this product.

See all of EMAG GmbH & Co. KG‘s catalogsRelated Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Workpiece grinding machine

- Cylindrical grinding machine

- High-precision grinding machine

- Tool grinding machine

- External cylindrical grinding machine

- Vertical grinding machine

- Internal cylindrical grinding machine

- 3-axis grinding machine

- Universal grinding machine

- High-performance grinding machine

- High-productivity grinding machine

- High-speed grinding machine

- Gear grinding machine

- Horizontal grinding machine

- 2-axis grinding machine

- Compact grinding machine

- Large-size grinding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.