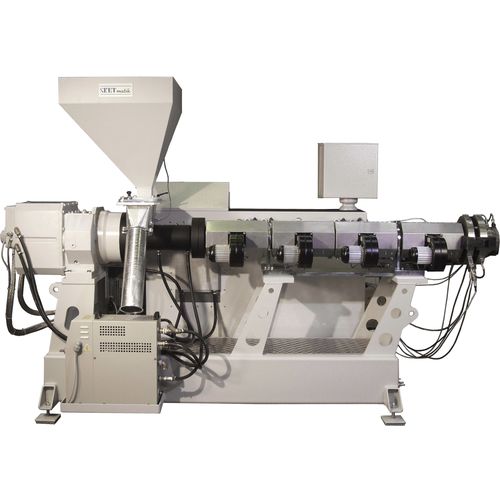

Single-screw extruder KE seriesgrooved feed

Add to favorites

Compare this product

Characteristics

- Number of screws

- single-screw

- Other characteristics

- grooved feed

- Output

Max.: 2,000 kg/h

(4,409.2452 lb/h)Min.: 10 kg/h

(22.0462 lb/h)- Screw diameter

Max.: 200 mm

(7.9 in)Min.: 25 mm

(1 in)

Description

Main Extruders

The main principle of the SKETmatik extruders is that they are manufactured to strict design principles and quality control to meet our customer’s requirements

Barrel & Screw are available with L/d ratios from 25 to 35. The screws are nitrided as standard The barrels are air cooled with water-cooling to the feed zone. The options of grooved feed zones with axial or spiral grooves are also available. Screws can be supplied with any geometry to meet specific requirements including: Barrier screws that can be combined with shearing and/or mixing zones The screws can be removed from the barrel either forwards or backwards Bi-metallic cylinders are available for use with abrasive materials. Screws in special material are also available

Drive As standard motor and gearbox are mounted in a U configuration and the motor is AC with a digital controller (flux vector). Alternative drive systems are available: Compact Geared Motor, Torque Motor Both of these systems have the advantage of taking minimal space, having low noise levels, and are environmentally clean being water-cooled. The AC digital controller can also be water cooled if required.

Barrel Temperature Control Efficient barrel temperature control is achieved using ceramic or glimmer heater bands and cooling fans blowing over specially designed copper cooling fins to improve cooling efficiency

Hopper: The hopper can easily be moved between three positions: OPEN; CLOSED and DISCHARGE.Hoppers with sight windows or level monitoring systems are also available.Pneumatic or other material handling systems can also be accommodated.

Catalogs

No catalogs are available for this product.

See all of Ematik GmbH‘s catalogsRelated Searches

- Extrusion line

- Thermoplastic extrusion line

- Screw extruder

- Pipe extrusion line

- Single-screw screw extruder

- Laboratory screw extruder

- Extrusion line for medical applications

- Cooling bath

- Extrusion cooling bath

- Coextruder

- Vented extruder

- Extrusion screw

- Tube cooling bath

- Spiral tube extrusion line

- Smooth bore extruder

- Water spray cooling bath

- Ceramic extruder

- Silicone rubber extruder

- Single-screw coextruder

- Strand cooling bath

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.