- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Semi-automatic heat sealer TCE 270for pre-cut sealsfor the food industrymedical

Add to favorites

Compare this product

Characteristics

- Operating mode

- semi-automatic

- Product applications

- for pre-cut seals

- Domain

- for the food industry, medical, for the chemical industry, for the pharmaceutical industry, for the cosmetics industry, packaging

- Other characteristics

- by induction, with conveyor, with touchscreen controls, variable temperature, conduction, pneumatic

Description

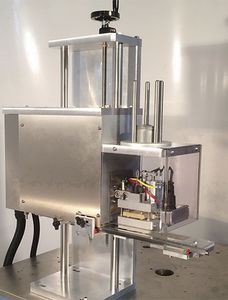

The semi-automatic sealer TCE 270 is a variant of the TCE 260.

The conveyor replaces the carriage and allows to avoid the need for an operator in front of the sealing post. Experience acquired on the previous generation of heatsealers allowed us to design an even more reliable machine from a technical point of view while simplifying its use. Ergonomics and machine configuration have been also improved (addition of a tactile control screen).

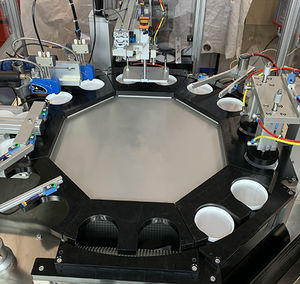

This machine is conceived for heatsealing pre-cut embossed aluminium seals on rigid jars. It exists by induction or by conduction depending on the nature of the jars to be sealed.

The operator places the jar on the conveyor. Some sensors detect the jars and trigger the sealing operations. Holding, pre-cut seals adjusting on jars and sealing are made in a single operation. The sealing as well as the centering of the seal are perfectly repeatable. Then, the sealed jars are evacuated toward, either an operator in charge of capping the jars, or an accumulation table.

The very quick and easy changes of size make this machine very versatile and flexible (diameters from 25 to 100 mm in standard). The module includes a vertical seals loader which has a capacity of about 500 to 800 seals and which is located at the front of the machine and so, it is easily interchangeable from one format to another.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Heat sealer

- Handheld heat sealer

- Automatic heat sealer

- Packaging heat sealer

- Continuous heat sealer

- Semi-automatic heat sealer

- Heat sealer for the food industry

- Medical heat sealer

- Rotary heat sealer

- Laboratory heat sealer

- Heat sealer for the pharmaceutical industry

- Heat sealer for the chemical industry

- Heat sealer for the cosmetics industry

- Heat sealer with conveyor

- Variable temperature heat sealer

- Induction heat sealer

- Membrane lid

- Membrane lid for the food industry

- Benchtop heat sealer

- Conduction heat sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.