- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

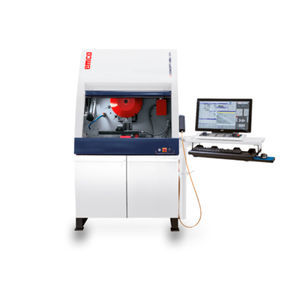

CNC turning machine CONCEPT TURN 2602-axisinclined bed12 tools

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 2-axis

- Structure

- inclined bed

- Number of tool stations

- 12 tools

- Applications

- for molds

- Performance

- high-precision

- Other characteristics

- compact

- Associated function

- milling, drilling, threading

- Diameter

250 mm

(9.84 in)- Spindle speed

6,300 rpm

(39,584.067 rad.min-1)- Maximum part length

255 mm

(10 in)- Maximum cutting diameter

85 mm

(3 in)- Bar capacity

25 mm

(1 in)- Axe X

100 mm

(4 in)- Axe Z

300 mm

(12 in)- Rapids on X

12 m/min

- Rapids on Z

12 m/min

- Nominal power

5.5 kW

(7.5 hp)- Maximum torque

35 Nm

(26 ft.lb)- Overall lenght

1,700 mm

(67 in)- Overall width

1,270 mm

(50 in)- Overall height

1,820 mm

(72 in)- Weight

1,100 kg

(2,425 lb)

Description

Integrated industrial PC with network and USB interface (front)

Programmable part collecting device

Easy2control user interface with 21,5" touchscreen

Safety technology CE compliant

Thermostable head stock with high drive power and C axis

Various clamping device and tool holder packages

DNC-Robotic Interface

Synchronized main spindle C axis with up to 1000 rpm

State of the art drive technology, servomotors with absolut encoders

Highlights

Integrated industrial PC with 21,5" touchscreen (MOC-Touch)

MOC: integrated PC

Extraordinary dynamics

Many automation possibilities

Easy2control user interface

Stable, industry-standard gray cast iron construction

Interchangeable controls (WinNC)

Various clamping devices and tool holder packages

Machine control panel with industrial touchscreen

Machine control panel with 16: 9 industrial touchscreen - 21.5 '' screen diagonal and Easy2control user interface.

Roller guides in the X and Z axes

High machining accuracy

Bar machining

Power chuck

Workpieces

Examples of use

Productive training

FMS / CIM systems

Jewel industry

Technical training projects

General tool and machine engineering

Options/Accessories

Parts catcher

Pneumatically operated parts catcher for the gentle unloading of the finished parts. The finished parts fall into a collecting box below the main spindle.

Chip conveyer

Chain feeding system with a dump-height of 1200 mm, suitable for: long steel shavings, snarl and wool chips for dry and wet machining

Pneumatic tailstock

The workpiece is supported automatically by a pneumatically operated quill with a stroke of 120 mm

Catalogs

INDUSTRIAL TRAINING

25 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.