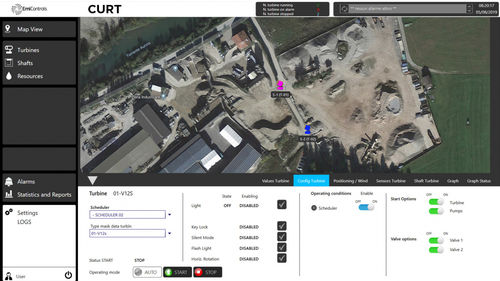

Management software CURTqualitycontrolSCADA

Add to favorites

Compare this product

Characteristics

- Function

- management, quality, control, SCADA, safety

- Type

- real-time

Description

The management software CURT can monitor all dust controllers and associated components of a plant and controls them independently in real-time – at the click of a mouse.

If certain work processes regularly generate dust, various inputs (such as information from the weather station or time control) can be used to define when and how the system is to be switched on or off automatically. This means that protection against dust is no longer in the hands of the employees, but happens automatically and energy-efficiently.

Thanks to CURT (Control Unit for Remote-controlled Turbines), the system always and only runs when it is needed.

CURT reacts to the following inputs:

Inputs

Each of the following inputs is separately definable for each dust controller machine in the system:

time control with calendar function

various atmospheric conditions, including wind, rain, temperature, humidity

photocell

Connection to SCADA systems is already active

CURT offers your team and company the following advantages:

Advantages

Autonomous: the plant runs completely automatically based on the predefined parameters, guaranteeing the consistent quality of dust abatement.

Time-saving: as the system runs autonomously, employees are not disturbed in their work processes.

Increased safety: the system can be controlled from the office at the click of a mouse, thus avoiding unnecessary personnel operations on the site.

Energy and cost-efficient: our dust suppression solutions are generally very energy-efficient and low in maintenance. Thanks to CURT and the pre-defined parameters, the machine only switches on when it is needed. This saves additional money and resources.

Catalogs

DUST MANAGEMENT

52 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.