- Products

- Catalogs

- News & Trends

- Exhibitions

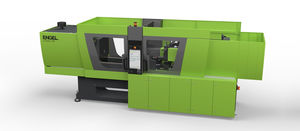

Horizontal injection molding machine e-speedhydraulicservo-electrichybrid

Add to favorites

Compare this product

Characteristics

- Closure

- horizontal

- Operation

- hydraulic, servo-electric, hybrid

- Other characteristics

- toggle, fast-cycling

- Clamping force

Min.: 2,200 kN

Max.: 6,500 kN

Description

The trend towards reduced wall thicknesses for thin-walled packaging products is placing ever greater demands on injection moulding machines. The fast e-speed is our answer. It delivers high performance on both the injection and clamping sides. Ensure profitable production of thin-wall plastic parts with our e-speed.

The Advantages of the e-speed Injection Moulding Machine

Cycle time < 2 sec. and absolute cleanliness

Reduced energy costs thanks to hybrid drive concept

Specially designed for thin wall plastic injection moulding

Picture shows mould interior during the production of a thin-wall plastic part

By avoiding oil mist formation and a closed lubrication system, no dirt can get onto your products. In addition, the extra-stable clamping platens ensure excellent platen parallelism. Perfectly suited for multiple moulds. All this with cycle times down to less than 2 seconds. Designed for the 24/7 production common in the packaging industry.

The hybrid drive concept reliably reduces any energy peaks thanks to kinetic energy storage. When the moving platen brakes, it absorbs the kinetic energy and releases it again when accelerating. Ideal for load-dependent electricity tariffs.

The all-electric clamping unit combined with hydraulic injection is powered by large batteries. The fast acceleration ensures a maximum injection speed of up to 1,200 mm/s. Maximum injection pressure of well over 2,000 bar even with just a few cm of injection stroke. This enables reliable and complete filling of cavities for thin-wall plastic parts – even with extreme flow-path-to-wall-thickness ratios.

VIDEO

Catalogs

Scope of products

29 Pages

Related Searches

- Injection press

- Horizontal injection press

- Hydraulic injection press

- Toggle injection molding machine

- Electric injection press

- Vertical injection press

- Fast-cycling injection molding machine

- Servo-hydraulic injection molding machine

- PET injection molding machine

- Hybrid injection molding machine

- Rubber injection press

- Medical device injection molding machine

- LSR injection molding machine

- Multi-component injection molding machine

- Modular injection molding machine

- Two-platen injection molding machine

- Elastomer injection molding machine

- Rotating table injection molding machine

- Sliding table injection molding machine

- Servo-electric injection molding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.