- Production Machines

- Plastics Processing

- Vertical injection molding machine

- ENGEL AUSTRIA GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

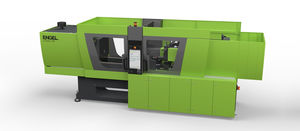

Vertical injection molding machine v-duoservo-hydraulic

Add to favorites

Compare this product

Characteristics

- Closure

- vertical

- Operation

- servo-hydraulic

- Clamping force

Min.: 4,000 kN

Max.: 36,000 kN

Description

The vertical injection moulding machine v-duo is the right machine for pressing, forming and overmoulding in one operation. Its precise clamping side with high platen parallelism ensures an exact result. With the injection unit, you functionalise the components after moulding in the same operation.

The advantages of the v-duo vertical injection moulding machine

Fully integrated injection unit

Particularly high plate parallelism

Complete periphery can be connected with Plug & Play

Benefit from our process know-how

Picture shows ENGEL's Centre for Lightweight Composites in St. Valentin

The v-duo is the only vertical press with a fully integrated injection unit. It moulds and functionalises components in just one cycle. You benefit from more economical production and save space.

The v-duo is the only vertical press with a fully integrated injection unit. It moulds and functionalises components in just one cycle. You benefit from more economical production and save space.

Picture shows closing side of vertical injection moulding machine

The clamp of the v-duo vertical injection moulding machine is designed for extra-high platen parallelism. Live measurement of tie bar elongation with automatic, separate control of the four pressure pads ensures consistently high part quality even under fluctuating conditions.

We are a total solution provider - with a broad portfolio of automation and peripheral equipment. All units in your production cell can be controlled via the central operating unit. This also applies to devices from third-party manufacturers. You benefit from consistent data sets and convenient operation.

VIDEO

Catalogs

Scope of products

29 Pages

Composite Technologies

13 Pages

Related Searches

- Injection press

- Horizontal injection press

- Hydraulic injection press

- Toggle injection molding machine

- Electric injection press

- Vertical injection press

- Fast-cycling injection molding machine

- Servo-hydraulic injection molding machine

- PET injection molding machine

- Hybrid injection molding machine

- Rubber injection press

- Medical device injection molding machine

- LSR injection molding machine

- Multi-component injection molding machine

- Modular injection molding machine

- Two-platen injection molding machine

- Elastomer injection molding machine

- Rotating table injection molding machine

- Sliding table injection molding machine

- Servo-electric injection molding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.