- Products

- Catalogs

- News & Trends

- Exhibitions

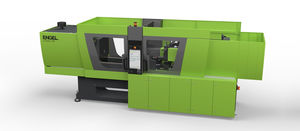

Horizontal injection molding machine flexsealservo-hydraulicfor rubberLSR

Add to favorites

Compare this product

Characteristics

- Closure

- horizontal

- Operation

- servo-hydraulic

- Treated material

- for rubber, LSR

- Clamping force

3,000 kN

Description

With our special flexseal machine, you can produce flat gaskets and O-rings made of rubber particularly efficiently. The compact dimensions allow you to use your production space effectively. Specially developed injection units ensure very high production precision - for the injection moulding of rubber with small shot weights.

The advantages of flexseal for rubber injection moulding

The well-thought-out total solution for O-rings and seals

Versatile solutions for material handling

Space-saving design

Over 40 years of experience in elastomer processing

Picture shows plastic O-rings

We offer you an optimal package for the production of flat gaskets and O-rings: screw units specially developed for rubber, compact machine design and easy accessibility of the tool space. If required, solid silicones can also be processed with our flexseal.

No matter how your raw material is supplied, the material feed of the flexseal can be flexibly designed. Whether fed via a roll holder or with an automatic strip feeder, the rubber is gently conveyed into the plasticising unit.

With an overall length starting at 4250 mm, the flexseal is extremely compact for a 3,000 kN machine. We achieve this with a special design of the clamping side and short injection units. This allows you to get the most out of your production area.

We have been developing solutions for the injection moulding of elastomers for decades. Our internal Competence Centre for this group of materials brings together application engineers, design engineers, service technicians and sales staff. The team is available to answer all your questions and concerns regarding the injection moulding of rubber and other elastomers.

VIDEO

Catalogs

No catalogs are available for this product.

See all of ENGEL AUSTRIA GmbH‘s catalogsRelated Searches

- Injection press

- Horizontal injection press

- Hydraulic injection press

- Toggle injection molding machine

- Electric injection press

- Vertical injection press

- Fast-cycling injection molding machine

- Servo-hydraulic injection molding machine

- PET injection molding machine

- Hybrid injection molding machine

- Rubber injection press

- Medical device injection molding machine

- LSR injection molding machine

- Multi-component injection molding machine

- Modular injection molding machine

- Two-platen injection molding machine

- Elastomer injection molding machine

- Rotating table injection molding machine

- Sliding table injection molding machine

- Servo-electric injection molding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.