- Products

- Catalogs

- News & Trends

- Exhibitions

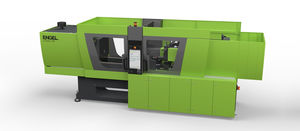

Horizontal injection molding machine e-motion TLelectricLSRtie-bar-less

Add to favorites

Compare this product

Characteristics

- Closure

- horizontal

- Operation

- electric

- Treated material

- LSR

- Other characteristics

- tie-bar-less

- Clamping force

300 kN, 500 kN, 800 kN, 1,200 kN

Description

Flexibility meets precision and efficiency. The e-motion TL injection molding machine combines the advantages of electric injection units with those of the tie-bar-less clamping unit. Thanks to this combination, the machine is particularly suitable for multi-cavity, liquid silicone and micro-injection molding applications, even in clean rooms.

The tie-bar-less, all-electric e-motion TL injection molding machine in action

Automotive fiber optics

Production of high-quality optical components thanks to precise, tie-bar-less clamping unit of the e-motion TL and gentle plasticizing of PMMA.

LSR micro injection molding

Micro parts for tear ducts made of silicone for ophthalmology: With a part weight of only 0.0005g, the precise e-motion TL is perfect for this application.

Two-piece vernier caliper

The tie-bar-less clamping unit of the e-motion TL offers maximum space for large molds and complex automation.

The advantages of the tie-bar-less, all-electric e-motion TL injection molding machine

The e-motion TL series combines the advantages of the electric injection unit with those of the tie-bar-less design. Thanks to this combination, you can produce with the lowest reject rate.

Precision level 1: Shot for shot thanks to the precise injection process of the electric injection unit

Precision level 2: Part for part thanks to the even clamping force distribution of the tie-bar-less clamping unit

The drive concept of the e-motion TL is designed to minimize cycle times while maximizing productivity. The machine makes perfect use of the advantage of the highly dynamic clamping drive, particularly in the production of high-volume precision parts.

Related Searches

- Injection press

- Horizontal injection press

- Hydraulic injection press

- Toggle injection molding machine

- Electric injection press

- Vertical injection press

- Fast-cycling injection molding machine

- Servo-hydraulic injection molding machine

- PET injection molding machine

- Hybrid injection molding machine

- Rubber injection press

- Medical device injection molding machine

- LSR injection molding machine

- Multi-component injection molding machine

- Modular injection molding machine

- Two-platen injection molding machine

- Elastomer injection molding machine

- Rotating table injection molding machine

- Sliding table injection molding machine

- Servo-electric injection molding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.