- Products

- Catalogs

- News & Trends

- Exhibitions

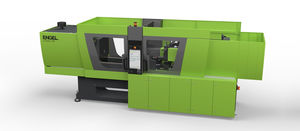

Horizontal injection molding machine victoryservo-hydraulictie-bar-lessmodular

Add to favorites

Compare this product

Characteristics

- Closure

- horizontal

- Operation

- servo-hydraulic

- Other characteristics

- modular, tie-bar-less

- Clamping force

Min.: 300 kN

Max.: 5,000 kN

Description

The tie-bar-less victory injection moulding machine is the ideal machine for a wide range of technical injection moulding applications and processes. The proven tie-bar-less technology ensures a particularly even clamping force distribution. For large moulds with low clamping force requirements, you only invest in the clamping force that is actually needed.

The Advantages of the victory Tie-bar-less Injection Moulding Machine

Compact design and lower investment costs

Simple integration of automation

Excellent platen parallelism for precise injection moulding

Mould protection for longer service life

Uniform clamping force distribution for high part quality

Fast availability thanks to stock machine programme

Picture shows compact tie-bar-less injection moulding machine from ENGEL

Mould size, rather than maximum clamping force, is often the key to optimal machine design. The victory tie-bar-less injection moulding machine enables production with machines that are one to two clamping force classes smaller. Helping you save valuable floor space and reduce acquisition costs.

Picture shows manufacturing cell with automation

The tie-bar-less injection moulding machines can be quickly and easily upgraded with robots, conveyor belts and a wide variety of peripheral equipment. Compact automation options and horizontal removal options save space.

Image shows plate parallelism by means of force dividers

The platen parallelism setting of each tie-bar-less clamping unit is precisely set up before delivery. The pre-tensioning of the patented force divider means that the platen parallelism remains unchanged even when the mould is clamped.

VIDEO

Catalogs

Related Searches

- Injection press

- Horizontal injection press

- Hydraulic injection press

- Toggle injection molding machine

- Electric injection press

- Vertical injection press

- Fast-cycling injection molding machine

- Servo-hydraulic injection molding machine

- PET injection molding machine

- Hybrid injection molding machine

- Rubber injection press

- Medical device injection molding machine

- LSR injection molding machine

- Multi-component injection molding machine

- Modular injection molding machine

- Two-platen injection molding machine

- Elastomer injection molding machine

- Rotating table injection molding machine

- Sliding table injection molding machine

- Servo-electric injection molding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.