- Products

- Catalogs

- News & Trends

- Exhibitions

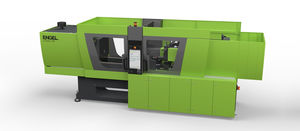

Horizontal injection molding machine duoservo-hydraulicmodulartwo-platen

Add to favorites

Compare this product

Characteristics

- Closure

- horizontal

- Operation

- servo-hydraulic

- Other characteristics

- modular, two-platen

- Clamping force

Min.: 3,500 kN

Max.: 55,000 kN

Description

The duo large injection moulding machine features a flexible layout and compact external dimensions. Suitable for various applications: from transport boxes to dashboard carriers to large rainwater tanks. Available with clamping forces from 3,500 kN to 55,000 kN, with more available on request.

The Advantages of the duo Large Injection Moulding Machine

Energy-saving production of large components

Compact size & flexible machine layout

Increase productivity with digital solutions

Less downtime due to modular injection unit

Image shows energy-saving production of large components

The efficient ENGEL ecodrive servo-hydraulics ensure high economic efficiency in the production of large-volume or large-area parts. It is included in the standard scope of the entire duo series. Thanks to the demand-based pump output, the motors are at rest and do not consume any energy when the machine is at a standstill during cooling, for example.

Demonstration Board

Single-stage process combining decoration and scratch-resistant surface protection in one production step through IMD and PUR coating.

Use of Recyclates in the Production of Transport Boxes

Transport boxes with recyclate in the core are produced on a large duo injection molding machine using the ENGEL skinmelt plasticizing process.

Production of Waste Collection Systems

With a clamping force of 55,000 kN, a shot weight of 27,500 g and, a cycle time of 140 sec, the duo 5500 produces 1100-L waste containers.

VIDEO

Catalogs

Scope of products

29 Pages

ENGEL combimelt

5 Pages

Related Searches

- Injection press

- Horizontal injection press

- Hydraulic injection press

- Toggle injection molding machine

- Electric injection press

- Vertical injection press

- Fast-cycling injection molding machine

- Servo-hydraulic injection molding machine

- PET injection molding machine

- Hybrid injection molding machine

- Rubber injection press

- Medical device injection molding machine

- LSR injection molding machine

- Multi-component injection molding machine

- Modular injection molding machine

- Two-platen injection molding machine

- Elastomer injection molding machine

- Rotating table injection molding machine

- Sliding table injection molding machine

- Servo-electric injection molding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.