- Production Machines

- Plastics Processing

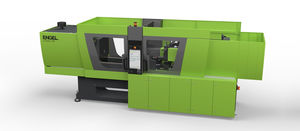

- Vertical injection molding machine

- ENGEL AUSTRIA GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

Vertical injection molding machine insert seriesservo-hydraulicrotating tablesliding table

Add to favorites

Compare this product

Characteristics

- Closure

- vertical

- Operation

- servo-hydraulic

- Other characteristics

- rotating table, sliding table

- Clamping force

Max.: 3,000 kN

Min.: 300 kN

Description

Our insert series is the best choice for insert moulding. The wide range of options and the flexible machine concept allow the machine to be adapted to your individual requirements. The integration of special automation is possible without any problems. You get an economical system and make a targeted investment.

The advantages of the vertical machine insert

Flexible machine concept thanks to a wide range of options

Small footprint for more productivity

Energy-efficient production with ecodrive

Wide range of options for mould temperature control

Picture shows insert injection moulding machine

The insert injection moulding machine is adapted precisely to your requirements. A wide range of options offers great scope: horizontal or vertical injection unit, multi-colour design, with sliding table or rotary table, for manual parts handling or with extensive special automation. We supply you with a vertical injection moulding machine made to measure.

Our vertical injection moulding machine is designed to take up as little space as possible. Especially versions with a vertical injection unit require very little floor space. The insert is therefore not only a solution for overmoulding inserts, but also for confined spaces.

Our servo-hydraulic drive concept ecodrive keeps your energy costs low. Thanks to intelligent pump control, we achieve low power loss and hardly any noise or heat emissions. You save expensive energy, use less cooling water and protect the environment.

In vertical machines for overmoulding inserts, the possibilities for guiding water for temperature control are often limited due to the design.

VIDEO

Catalogs

Related Searches

- Injection press

- Horizontal injection press

- Hydraulic injection press

- Toggle injection molding machine

- Electric injection press

- Vertical injection press

- Fast-cycling injection molding machine

- Servo-hydraulic injection molding machine

- PET injection molding machine

- Hybrid injection molding machine

- Rubber injection press

- Medical device injection molding machine

- LSR injection molding machine

- Multi-component injection molding machine

- Modular injection molding machine

- Two-platen injection molding machine

- Elastomer injection molding machine

- Rotating table injection molding machine

- Sliding table injection molding machine

- Servo-electric injection molding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.