- Hydraulics - Pneumatics

- Pump

- Radial piston pump

- ENGINEme GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

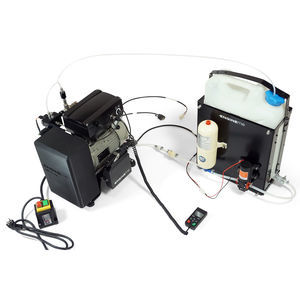

High-pressure pump HPP 200radial pistonwaterfor chemicals

Add to favorites

Compare this product

Characteristics

- Technology

- radial piston

- Fluid

- water, for chemicals, fuel oil, diesel fuel, for gasoline

- Mobility

- stationary

- Domain

- industrial, for the chemical industry, laboratory, for engine

- Applications

- high-pressure, booster, conveying, injection, spraying

- Material

- stainless steel, steel, PTFE

- Fluid specification

- for low-viscosity fluids, for mineral oil, for AdBlue, for hazardous fluids, for fluids with lubricating properties, for hot oil, for high-purity fluids

- Protection level

- chemical-resistant, wear-resistant, for harsh environments, robust

- Other characteristics

- compact, low-noise, lubricated, low-pressure, fixed-displacement

- Flow

Max.: 1.6 l/min

(0.42268 us gal/min)Min.: 0 l/min

(0 us gal/min)- Pressure

Max.: 200 bar

(2,900.755 psi)Min.: 10 bar

(145.038 psi)- Fluid temperature

Max.: 130 °C

(266 °F)Min.: -30 °C

(-22 °F)- Length

119 mm

(5 in)- Width

81.3 mm

(3.2 in)- Height

162 mm

(6.38 in)- Weight

1.45 kg

(3.2 lb)

Description

The HPP 200 is a very compact high-pressure pump that is particularly suitable for pressurization when pumping low-viscosity liquids. The basic version of the pump is designed for a continuous operating pressure of 200 bar. The separation between the high-pressure circuit and the lubricated tappet drive enables non-lubricating liquids (e.g. water, gasoline, etc.) to be conveyed.

No compromises have to be made in terms of service life, even at high speeds. The HPP 200 is used, among other things, as a high-pressure pump for combustion engines, heating water and atomizing systems. On request, we will be happy to check the possibility of application-specific adjustments in terms of delivery rates or chemical resistance of the materials used.

The HPP 200 is a valve-controlled radial piston pump with constant displacement. At the low-pressure inlet, the medium is pumped into the pump under low pre-pressure. The pump shaft is set in rotation by an external drive, with the torque being transmitted via a form fit on the drive journal.

The pump shaft has an eccentric on which the pressure tappet rests. The eccentric rotating with the pump shaft sets the pressure tappet in a cyclical upward or downward movement, which alternately reduces and increases the volume in the high-pressure chamber. The control valves integrated in the pump ensure that the high-pressure chamber is filled with liquid during the downward movement and is displaced into the high-pressure outlet during the upward movement. A sealing system is located between the high pressure chamber and the eccentric chamber, which prevents an exchange of the conveying and lubricating medium.

Catalogs

HPP 200 High Pressure Pump

7 Pages

HPCU 200 BASIC - EN

10 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.