Functional testing machine SCCautomaticmanualsemi-automatic

Add to favorites

Compare this product

Characteristics

- Test type

- functional

- Operating mode

- automatic, manual, semi-automatic

- Test material

- printed circuit

- Sector

- industrial, for laboratories

- Technology

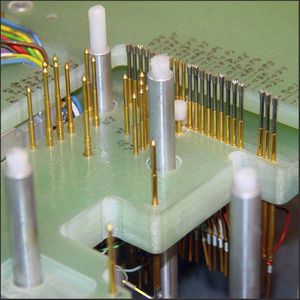

- optical, contact

- Other characteristics

- stand-alone

Description

Do you want to test your products reliably, quickly, and economically in the smallest possible space?

The Smart Contact Cell enables an ICT/FCT test with subsequent optical and haptic EOL test during loading and unloading in a very small space.

It is therefore ideal for automating your testing tasks – independently or in combination with manual, semi-automatic, and fully automatic assembly solutions.

Flexibility is achieved by quickly and easily interchangeable mounting and contacting elements. A sustainable investment for your variants and production volume scenarios!

The Smart Contact Cell is a stand-alone tester featuring two workpiece carriers that move simultaneously above and below each other. This enables the parallel feeding and removal of the DUTs, which significantly reduces handling times. So wird eine parallele Zuführung und Entnahme der Prüflinge ermöglicht, was die Handlingzeiten erheblich reduziert.

Cycle time-neutral removal or feeding of components thanks to intelligent tandem shuttle system

Transport and contact time of only approx. 3 seconds

Possible accommodation of test equipment in the system and integration of scanners in the insertion area

Possible extension of the system with handling or robot systems

Dimensions of the standard system approx. 1570 / 750 / 1700 mm (L/W/H)

Particularly flexible thanks to quick exchange of fixture kits

Catalogs

No catalogs are available for this product.

See all of ENGMATEC GmbH‘s catalogsRelated Searches

- Test machine

- Test cabinet

- Test stand

- Automatic test machine

- Temperature test cabinet

- PC-controllable testing machine

- Automatic test stand

- Industrial test machine

- Laboratory test machine

- Environmental test cabinet

- Test chamber on casters

- Electronic testing machine

- Floor-standing test cabinet

- Manual test stand

- Quality control test chamber

- Manual test machine

- Automatic test chamber

- Electrical equipment test cabinet

- Test fixture

- Semi-automatic test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.