Assembling system

Add to favorites

Compare this product

Description

Our automation solutions allow the linking of a wide range of manufacturing processes, from feeding to packaging. All of these solutions employ sophisticated test technology – our core competence.

Depending on the specific requirements, we can implement the systems as manual workstations, rotary indexing tables, linked cells, or as complete inline production systems. For us, it goes without saying that all workstations must always have an ergonomic and safe design.

The use of high-quality sensor technology offers 100% process control. In addition, all relevant data is recorded and integrated into workflow and MES systems to ensure end-to-end traceability.

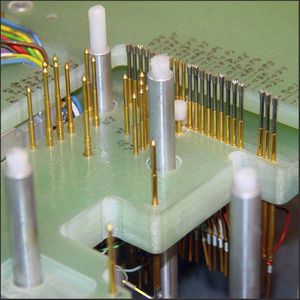

The system with manual insertion area enables the integration of diverse processes.

Components with a scalable degree of automation guarantee flexible production figures.

Various processes from feeding to AOI can be linked and designed as a fully automatic line.

Benefit from safe and stable feeding through high autonomy – with ENGMATEC feeding systems.

Whether manual insertion or automated feeding, whether ordered in a defined transport container or as bulk material – we develop and integrate various feeding systems for the needs-based feeding of system components.

Spiral conveyors, tray handlers, and other flexible solutions are possible. Our efficient systems reduce your employees’ workload and thus your costs.

Catalogs

No catalogs are available for this product.

See all of ENGMATEC GmbH‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.