What is SFM

It's for professionals who want to see the big picture, not only partial measurements with calipers and optical comparators.

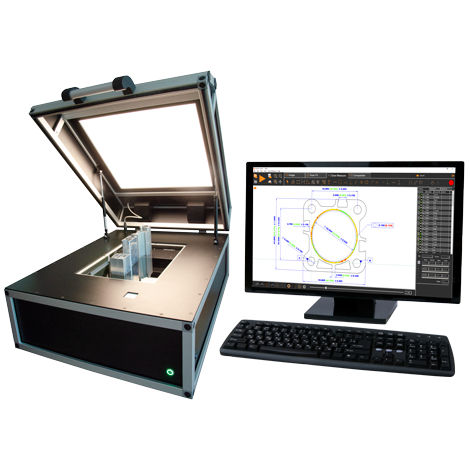

Scan Fit and Measure is 2D system for off-line measurement and inspection of profile geometry. It is used as a quality control tool allowing various types of production facilities to benefit by reducing costs and minimizing product deviations. The flatbed scanner technology is suitable for measurement of profiles from aluminum, plastic, rubber, silicon and medical tube extrusion.

Easy to set up and use, the 2D measurement system delivers instant PASS/FAIL evaluation based on a rich set of customer’s predefined geometric dimensions and tolerances. It provides a visual comparison of the scanned image to the CAD model based on the precise measurement of size, position, wall thickness and GD&T (Geometric Dimensioning and Tolerancing).

Large field of view area of 300mm x 400mm (11 3/4" x 15 3/4") allows sizable and multiple part measurement thus speeding quality control and ensuring an intact and continuous production flow. TEST

System Features

• - Open-standard data output for integration with other information and reporting systems

• - Open-standard data input for integration with other (3rd party) measuring devices

• - Up to 300mm x 400mm (11.3/4" x 15.3/4") field of view, up to 130mm (5.1/8") part height

• - Rugged design for shop floor operation

• - Multiple parts measured at once for speed and reduced workload

• - Separate profile, dimensional and comparator views for unambiguous evaluation

• - One-time CAD measurement template preparation

• - Constructed features for comprehensive measurement