- Environment - Health - Safety

- Waste Treatment

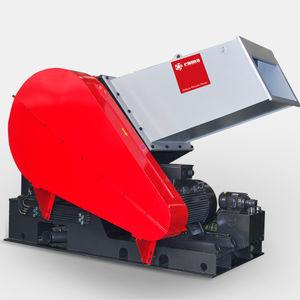

- Rotor granulator

- ENMA Granulator (China) Co.,Ltd

Soundproofed granulator GS series rotorfor plastic wastecompact

Add to favorites

Compare this product

Characteristics

- Type

- rotor

- Applications

- for plastic waste

- Other characteristics

- compact, soundproofed

Description

The GS compact/sound proof granulators are designed with a complete sound proof enclosure resulting in an extremely quiet operation. Different rotor designs are available in widths ranging from 300 mm to 1400 mm with a diameter of 300 mm. The completely welded cutting chamber in conjunction with the "V" type rotor design ensures dependability in operation and universal application use. While it delivers excellent sound proofing capabilities, it still offers easy and quick access to the cutting chamber during rotor and stator knife changes, servicing or screen changes. The sound dampening material used in these machines is based on the latest technological research.

Knives are adjusted outside of the machine

Compact design

Different rotor types available

Soundproofed housing

Strong tangential infeed

The cutting geometry of the GS series allows even voluminous materials to be ground. The complete GS series line achieves a high quality regrind independent of the material type or form such as injection moulding parts, blow moulding parts, profiles, sheets, film, etc. The 300 series GS machines are mainly used in inline operations for processing of rejected products, or runners and sprues. The small footprint and easy movability make the machines very easy to place in existing operations.

- Security devices are the top concern of ENMA

- Compact type design

- Manual hydraulic opening device

- Design of integral type control cabinet

- Design of discharge without bridged

- Heavy duty rotor

VIDEO

Catalogs

No catalogs are available for this product.

See all of ENMA Granulator (China) Co.,Ltd‘s catalogsOther ENMA Granulator (China) Co.,Ltd products

Granulator

Related Searches

- Grinding mill

- Waste shredding machine

- Pelletizer

- Horizontal grinding mill

- Single-shaft shredding machine

- Vertical grinding mill

- Primary shredding machine

- Wood shredding machine

- Two-shaft shredder

- Metal shredding machine

- Rotor lump breaker

- Paper shredding machine

- Plastic shredding machine

- Rugged shredding machine

- Rotor pelletizer

- Waste lump breaker

- Plastic pelletizer

- Compact shredding machine

- Waste granulator

- Tire shredder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.