- Environment - Health - Safety

- Waste Treatment

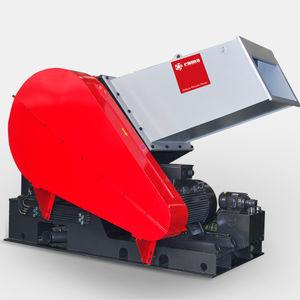

- Rotor granulator

- ENMA Granulator (China) Co.,Ltd

Rotor granulator GE series for plasticsfor wastefor the plastics industry

Add to favorites

Compare this product

Characteristics

- Type

- rotor

- Applications

- for plastics, for waste

- Sector

- for the plastics industry

- Other characteristics

- soundproof

Description

GE series economy granulator adopts high efficiency double-scissors cutting technology of rotor. GE500 series has various of rotor type available, width ranging from 500 to 2000mm with diameter of 500mm. The whole welded steel structure and the V-shaped rotor design. It is suitable for the recycling of many kinds of materials, running smoothly and reliably. GE500 series granulator is equipped with manual or hydraulic box opening system, which easy to open and clean, to maintain the crushing chamber, so as to adjust and fix the blades, clean and replace screen. The series is with the latest developed soundproof material hopper, reliable technology and sound insulation effect.

GE series is used economically for handling the defects during injection molding, sprues, pipes, profiles, sheets, films and nozzles. It is everlasting and easy to clean with longer life. ENMA's reliable V-shaped cutting technology not only retains all the advantages of the original cross-cutting technology, but also has new characteristics. Cutting point only at the place where the blades cross instead of the whole blade. It considerably ensures lower noise, less powder and prolongs the service life, thus saving the energy. "V"-cutting technology drives the materials towards the centre of the rotor and solves the problems such as stacking materials inside, heat from rubbing and excessive side-wall friction.

GE500/500

GE500/700

GE500/1000

GE500/1400

- Electrical type of hydraulic opening system

- Multi-knife cutting type

- Machine design of open type

- Conveyor + Granulator + Suction system

- S-Universal type rotor

- H-Heavy duty rotor

VIDEO

Catalogs

Other ENMA Granulator (China) Co.,Ltd products

Granulator

Related Searches

- Grinding mill

- Waste shredding machine

- Pelletizer

- Horizontal grinding mill

- Single-shaft shredding machine

- Vertical grinding mill

- Primary shredding machine

- Wood shredding machine

- Two-shaft shredder

- Metal shredding machine

- Rotor lump breaker

- Paper shredding machine

- Plastic shredding machine

- Rugged shredding machine

- Rotor pelletizer

- Waste lump breaker

- Plastic pelletizer

- Compact shredding machine

- Waste granulator

- Tire shredder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.