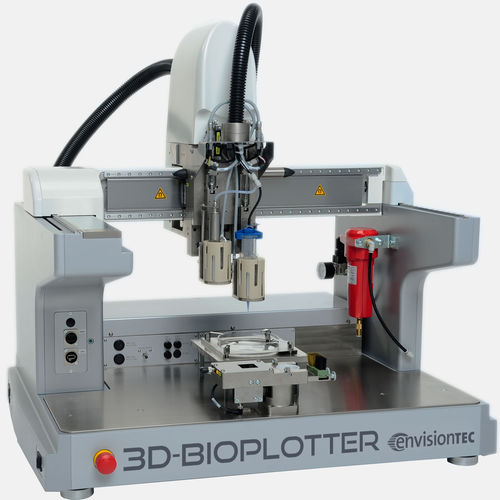

The 3D-Bioplotter® System is a versatile rapid prototyping tool for processing a great variety of biomaterials for computer-aided tissue engineering (CATE), from 3D CAD models and patient CT data to the physical 3D scaffold with a designed and defined outer form and an open inner structure. The 3D-Bioplotter® has the capacity of fabricating scaffolds using the widest range of materials of any singular rapid prototyping machine, from soft hydrogels over polymer melts up to hard ceramics and metals. Complex inner patterns can easily be designed using the 3D-Bioplotter® software to control the mechanical properties, increase cell adhesion, as well as improve the flow of nutrient media throughout the interconnecting pores of the printed implants.

• Designed for research groups new to the field of tissue engineering with few requirements in parallel material processing and automation.

• Consisting of the same basic hardware and software as the Manufacturer & Developer Series, but lacking modular capability and platform temperature control.

• Not upgradable to the same capability of the Developer or Manufacturer Series.

A simple process: A liquid, melt, paste or gel is dispensed from a material cartridge through a needle tip from a 3-axis system to create a 3D object.

One single requirement: The material to be used must, through a physical or chemical reaction, solidify.

A world of possibilities: The widest range of materials of any 3D printing technology can be processed.

MACHINE PROPERTIES

Filters Included: Particle

Platform Temperature Control: No

Max Heads: 2

Head Temperature Range: High: 30° – 250°C (86° – 482°F)