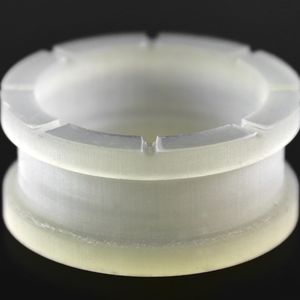

Yellow 3D printing resin E-Tool 2.0industrial

Add to favorites

Compare this product

Characteristics

- Color

- yellow

- Applications

- industrial

Description

Now available in beta, E-Tool 2.0 is filled with Barium Borosilicate Glass, known for its heat and chemical resistance, to deliver injection molds that can withstand high heat and pressure. Combined with EnvisionTEC’s 3D printing technologies, E-Tool 2.0 delivers highly accurate tooling with an exceptionally smooth surface finish.

Now in testing with a German injection molding company, E-Tool 2.0 molds were successfully used for injection molding of Polypropylene (PP; Injection temperature: 370ºF to 400ºF Mold Hold Press Pressure: 22T) and Polyethylene (PE; Equistar 6580. Injection temperature: 325ºF to 365ºF. Mold Hold Press Pressure: 22T).3

*EnvisionTEC highly recommends requesting a sample or benchmark in this material to ensure the material meets your specific injection molding needs.

PHYSICAL PROPERTIES

Tensile Strength: 49.4 MPa

Elongation at Break: 1.46%

Tensile Modulus: 4660 MPa

Flexural Strength: 82 MPa

Flexural Modulus: 5220 MPa

Izod Impact Notched: 18.9 J/m

HDT at 1.8 MPa (264 psi): 63°C

Shore Hardness, D: 89

Viscosity at 30°C: 1460 cP

Minimum wall thickness: 2.5 mm

Color: Yellow

RECOMMENDED MACHINES

Micro Plus Advantage, Vida, Vida HD, Ultra 3SP, Ultra 3SP HD, Vector 3SP, Vector HD 3SP, Xtreme 3SP, Xede 3SP, Micro Plus HD, Perfactory P4K Series

APPLICATIONS

Aerospace, Entertainment, Automotive, Education, Manufacturing

Catalogs

No catalogs are available for this product.

See all of Envisiontec‘s catalogsRelated Searches

- Additive manufacturing machine

- Industrial 3D printing machine

- Plastic 3D printing machine

- Model making 3D printer

- High-speed 3D printer

- ABS 3D printing machine

- Metal additive manufacturing machine

- Large-format 3D printing machine

- 3D printing resin

- Medical additive manufacturing machine

- Dental additive manufacturing machine

- Table-top 3D printer

- Resin 3D printer

- Polymer 3D printing resin

- Industrial 3D printing resin

- Continuous 3D printing machine

- Model making 3D printing resin

- Dental 3D printing resin

- White 3D printing resin

- Mold manufacturing 3D printer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.