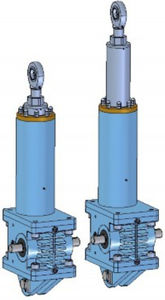

High load capacity cylinder ELZ serieselectricscrew spindleworm gear

Add to favorites

Compare this product

Characteristics

- Type

- electric

- Technology

- screw spindle, worm gear, trapezoidal screw

- Protection class

- robust

- Applications

- for lifting applications

- Other characteristics

- high load capacity, motorized

- Force

Min.: 5 kN

Max.: 350 kN

- Torque

Min.: 1.65 Nm

(1.217 ft.lb)Max.: 417.7 Nm

(308.08 ft.lb)- Speed

Min.: 0.5 m/min

Max.: 5.4 m/min

- Ambient temperature

Min.: -30 °C

(-22 °F)Max.: 80 °C

(176 °F)

Description

FREN Electric cylinders are an advancement of our standard program. By thought

construction is an electrical cylinder in the situation also components out to be taken up. The

lift link inside electrical cylinders is protected by the tubing system from any damage by

environmental influences and is approximately to rotate secured.

In the FREN Electric cylinder there is a robust worm gear pair driving a trapezoid thread

spindle. The gear box is made of nodular graphite cast iron 50 fit high loads and meeting high safty standards. The worm is hardened and ground and running on tapered roller bearings.

The worm wheel is made of high-strength material which is particularly resistant to abrasion;

it is mounted between deep groove ball thrust bearings. The thrust tube consists of steel and is outside polished and chromium plated. The spindle ends can be supplied after customer's

request also stainless.

The ELZ5 to ELZ350 line ist the worm gear alternatively filled with grease or oil and the

tubing system is lubricated with grease on delivery and fit for operating temperatures ranging

between -30°C and +80°C. To be increased the trapezoid thread spindle is the life span

additionally coated with lubricating varnish by better fail-safe characteristics to be achieved

and thus.The operating factor at maximum load is 20% per hour 30% per 10 minutes.

The trapezoid thread spindles are stand single-threas double-thread three-thread and fourthread execution. For higher demands with regard to lifting speed and operating factor we use ball screw spindles. FREN Electric cylinders are fitted with blue prime coat (RAL 5012)

Catalogs

No catalogs are available for this product.

See all of Enzfelder GmbH‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Cylinder

- Actuator

- Linear actuator

- Electric actuator

- Lifting table

- Scissor lifting table

- Stationary lifting table

- Hydraulic lifting table

- Compact cylinder

- Electric cylinder

- Screw jack

- Stainless steel cylinder

- Stainless steel actuator

- Metal screw jack

- Mini actuator

- Screw cylinder

- Translating screw jack

- Rotating screw jack

- Positioning cylinder

- Ball screw cylinder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.