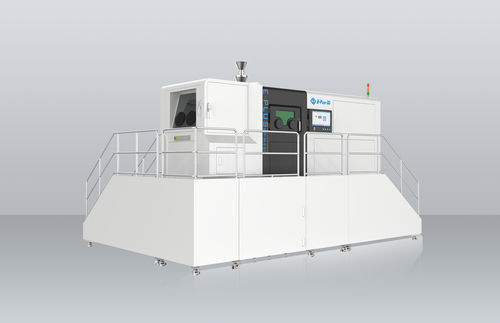

EP-M450 Metal 3D Printer

With a building chamber size of 455*455*500mm Eplus3D Introduces EP-M450 to the successfulline of MPBF™ 3D printers. The complete open systemmakes EP-M450 a very powerful tool for large scaleproduction for our customer to access different metal powders like titanium, aluminum, nickel alloys and stainless steel, etc EP-M450 is aiming to output the large parts with its high performance and high accuracy.

HIGH QUALITY

• - Printed parts' density > 99.9 %, deviation in parts' mechanical properties < 5 %.

• - The optimized gas flow design ensures efficient removal of smoke and splashes as well as achievement of uniform and consistent full size printing.

• - Dynamic software with ability to divide the model into different sections like upper and lower surfaces, core areas and small areas etc. Different process parameters can be applied individually to these parts for high printed part quality.

• - Repeatable positional accuracy along Z-axis of building direction ≤±5 μm.

• - Overlapping deviation with dual laser printing ≤±0.1 mm. Overall mechanical properties of the printed part remains same when compared to printing results with the single laser machine.

HIGH EFFICIENCY

• - Build chamber size (X*Y*Z): 455*455*500 mm³, build chamber volume >100 L.

• - Printing with increased layer thickness can be realized, increasing the production capacity.

• - With in-house developed processing software (EP-Hatch), optimized scanning strategies can be achieved yielding reduced print duration.

• - Optional dual laser system with 2*500 W fiber lasers increases printing efficiency by 70 %.